Rice straw

The era of recycling in construction

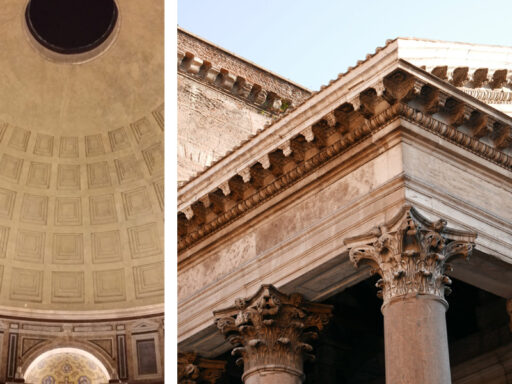

Environmental sustainability is a widely debated issue that over the years has brought about a new awareness and greater sensitivity to respect for the planet and the resources available in nature. In the construction sector, these issues are considered increasingly important as recent studies have shown that buildings are the main cause of global pollution. For this reason, it is necessary to adopt alternative solutions that involve the use of local raw materials since, in addition to being widely available, they reduce the energy consumption to produce them and the smog to transport them. Furthermore, the use of resources from the recycling process is very advantageous; this is the case of rice straw, a residual element coming from food production, which in recent decades has shown to have great potential in construction.

Now let’s see how straw houses can be considered a valid alternative for the future of the residential sector.

The recovery process and the materials

As mentioned above, the food production of rice can prove to be advantageous from the point of view of the recovery of apparently waste materials. This is a 360 ° sustainable approach since in addition to avoiding waste and providing useful materials in other production sectors, it favors the design of buildings with low environmental impact and reduced energy consumption.

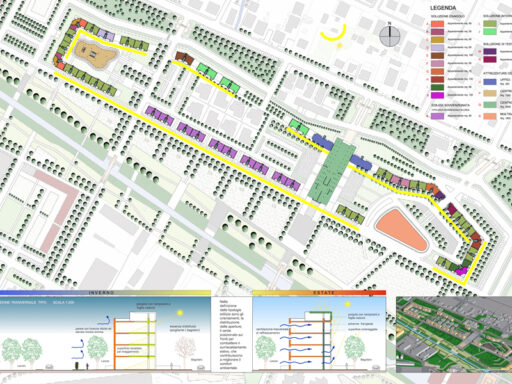

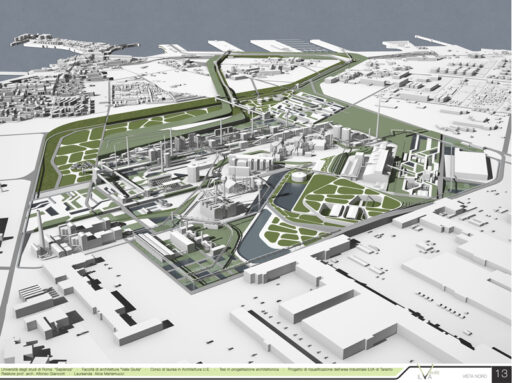

In Italy and specifically in the Po Valley area, rice production is the most consistent at a national level and quite relevant at a European level. This phenomenon is to be considered a great opportunity as waste such as straw and husk are abundant and very useful in construction. Through careful enhancement of these materials, it will be possible to achieve optimal results from an energy and performance point of view.

Recycling consists of successive steps: when the rice is cut, the straw is collected and removed from the field. According to traditional production processes, the straw is burned to be eliminated, resulting in the production of carbon dioxide. The recovery of rice straw avoids this step, drastically reducing the pollution associated with it. During the industrial production of rice, the outermost layer of the grain, called husk, is usually thrown away. However, this substance has proved useful for the production of insulators and mortars used in the laying of screeds and is thus recovered. In fact, it is a very light material, made of cellulose and resistant to the formation of mold. Finally, the chaff is also recovered, a floury substance deriving from the rice bleaching process.

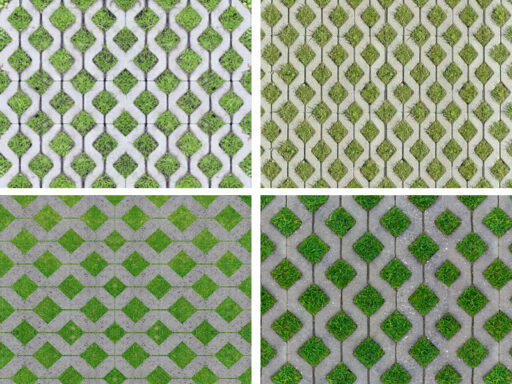

These three materials, once recycled, are used for the production of compositional elements essential for the construction of sustainable buildings. Examples are frames made of wood and straw, mortars, insulating plasters, ecological screeds and substances used for finishes such as those based on husk. These are high-performance products: lightness, breathability, heat capacity, non-toxicity, ease of installation and versatility of use.

Straw houses

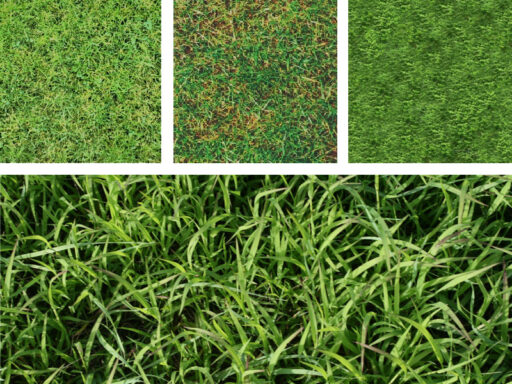

As already mentioned, experimentation and recovery of alternative materials present in nature, capable of providing high performance, is increasingly frequent. Among these, rice straw, thanks to its properties, is well suited for the manufacture of curtain walls. In fact, the material is able to insulate thermally and acoustically, as well as ensuring high breathability in order to avoid the formation of condensation and mold. Widely present in nature, it is a low-cost and easy-to-install material. Furthermore, being composed of cellulose, lignin, silica and minerals, it is very similar to wood. The fiber is 100% ecological as in addition to absorbing CO2 it is biodegradable; it also has a high durability over time as it is less prone to mold than straw resulting from the processing of other cereals. Rice straw is used for frame construction and is also capable of withstanding loads. Houses built with this material ensure greater living comfort as they do not provide for the formation of surface condensation, thanks to the breathable capacity of the raw material. In this way, the interiors of the straw houses are healthier and more balanced from a hygrometric point of view.

Installation

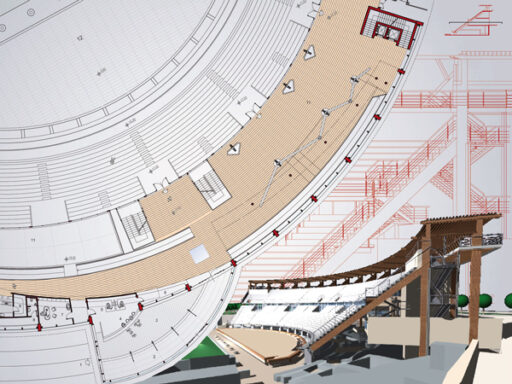

Since sustainability issues currently constitute the founding basis of every intervention, rice straw is the raw material for transferring the project “from paper to reality”. In this regard, as regards the installation, the material can be laid in the traditional way, through wet or dry substances. The first process involves the assembly on site of the recovery material with water and clay, the second consists in the dry assembly of pre-made panels. The latter is a faster procedure that allows greater convenience and cleaning on site.

Rice straw has proven to be an optimal solution both for renovations, progressively replacing plasterboard, and for new buildings aimed at providing healthy and environmentally friendly products. In fact, thanks to its low transmittance values, today it is also used for the insertion of thermal coats. In this way, the building can move to class A ++++ and become passive. However, it should be pointed out that the solution is not suitable for any type of building, such as historic buildings and listed buildings, where the most common alternative is represented by thermal plasters.

But what are the costs of straw houses?

It depends on the building blocks of the house, on the size, on the type of materials and finishes chosen by the client. It can be said that the savings are around 20% compared to the cost of a house built according to traditional construction. Quantifying, the cost turns out to be around 1500 euros / sqm. It should be noted that, in the face of an expense similar or equal to a standard property, you will enjoy a passive house, able to ensure high economic savings over time.

Examples of thatched houses

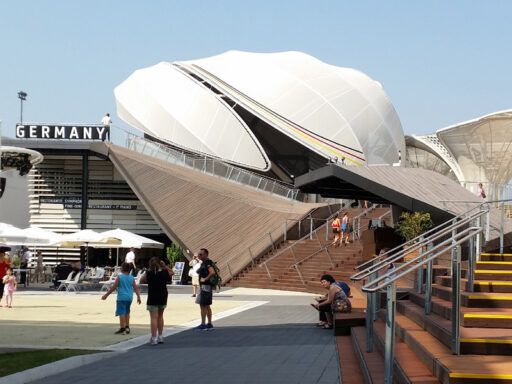

The concept of sustainable building must embrace the entire construction process, starting from the design idea, the choice of materials, up to the realization. In fact, it is necessary to contain energy consumption and costs, to opt for resources present in nature or recycled, to avoid the production of pollution as much as possible and to involve local entrepreneurial realities. It is a 360 ° modus operandi, capable of demonstrating that sustainability, if considered in its entirety, returns optimized housing solutions. Let’s now see two examples of rice straw construction.

Casa Quattro – LCA – Milan

The detached house takes up the archetype of the Lombard rural houses, with the sloping double pitched roof, the compact and simple shape. The building is distributed over two floors with the living area on the ground floor and the sleeping area inside the attic. The design process involved the use of rice straw with a high insulating capacity, wood for the manufacture of the frames and a high-performance coat to improve the conditions of microclimatic comfort. As can be seen, completely natural materials were used. Each choice was made according to a sustainable approach: recycled materials, natural resources and ecological systems characterize the entire building. The interiors boast fine finishes such as oak parquet and double windows, with the dual purpose of ensuring comfort and well-being for the user and ensuring good energy savings and consequently economic savings.

Alchemilla B&B – Tiziana Monterisi (Ricehouse) – Gressoney

One of the first examples of accommodation built entirely with natural materials, where the ecological philosophy concerns the architectural choices but also those relating to the management of the b & b, from services to food at km 0. Located in Valle d’Aosta, the building is It was designed to give its guests a healthy and comfortable experience, thanks to the naturalness of the materials and the non-toxic components. The load-bearing walls consist of a wooden structure and rice straw that functions as a filling and insulator. The finishes originate from the mix of lime and waste from rice production. The entire structure is immersed in the mountain environment and boasts a low impact thanks to the non-emission of CO2 and the ability of the materials to be recycled at the end of their life. The Alchemilla b & b can be considered a passive building and designed according to innovative and 100% sustainable standards.

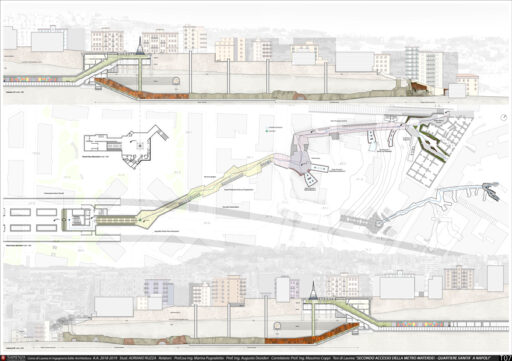

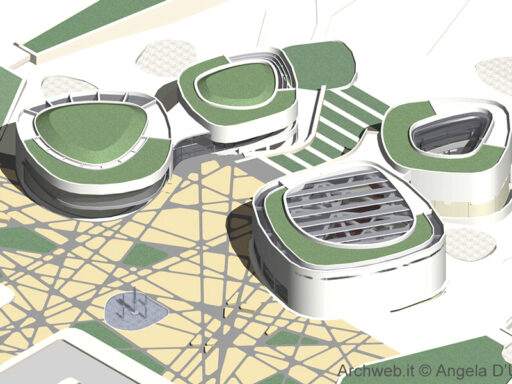

To view a project that has adopted local materials and sustainable solutions in full respect of the environment click here