Fabrics for facades

The fabrics could be the next big news in the facades

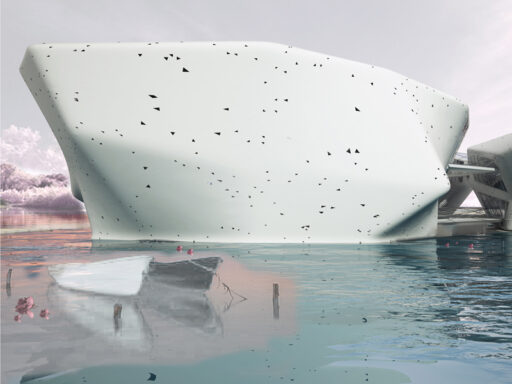

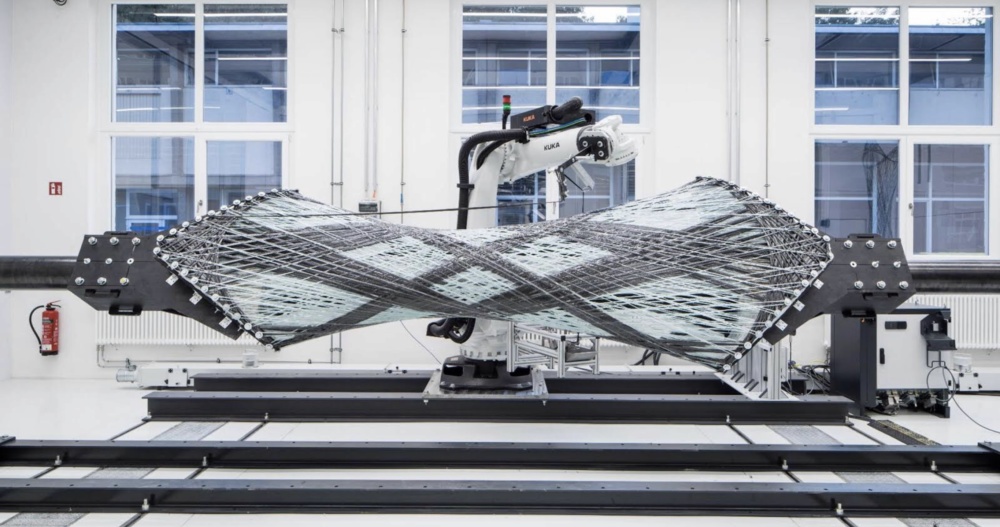

Researchers from the Institute of Building Structures and Structural Design in Stuttgart, Germany, are developing flexible composite fiber structural assemblies for the Elytra pavilion, a domed structure made of woven glass carbon fibers. (Institute for Light Structures and Conceptual Design)

Humans have used the fabric to create shelter for thousands of years. If a number of groundbreaking researchers and designers make their way, however, applications of textile-based architectural elements have the potential to play an important role in shaping the future of architectural surfaces as well.

Through scales and application methods, research into the use of textile-based elements in architecture has increased over the past 15 years as teams of professionals and universities in Europe and the United States have embraced applications of robotic weaving, carbon fiber fabrics custom designed and experimental fabric facades. With the aim of enveloping ever larger structures, creating unique sensory experiences, and designing a more sustainable future, new fabric applications have the potential to change the face, look and feel of architecture as we know it.

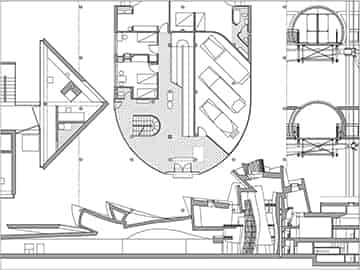

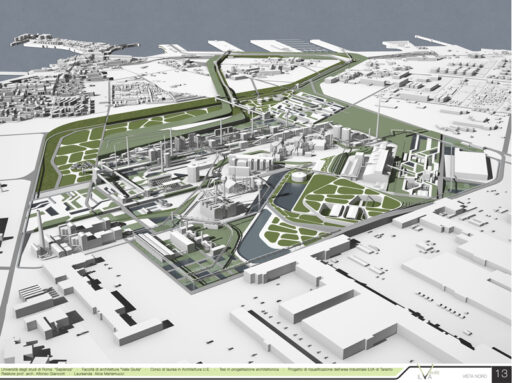

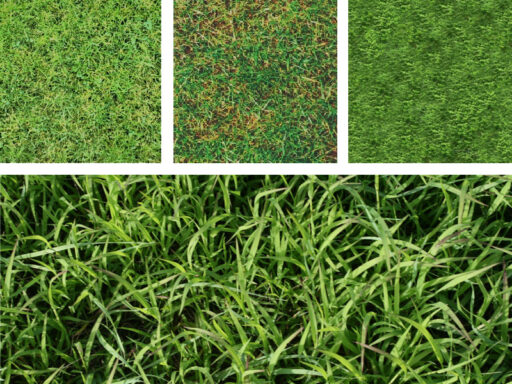

Composite fiber dome – Institute of Building Structures and Structural Design

Universities in Germany are leading research, most notably at the Institute of Building Structures and Structural Design (ITKE) in Stuttgart, where Professor Jan Knippers has developed methods for creating fabrics from foldable composite elements, including carbon and glass fibers. .

Knippers is currently working on developing the latest iteration of its Elytra pavilion, a prototype “Fiber Composite Dome” structure that will make its debut at the National Garden Show in Heilbronn, Germany, later this year. The over 12-meter wide dome is made of woven glass carbon fiber elements connected only by steel washers and bolts. To create the pavilion, Knippers designed a geometric series of 60 groups of resin-impregnated fiber bodies that come together to distribute structural loads from the dome in an elegant and efficient way. The precision-driven arrangement also extends to the size and organization of the individual carbon fibers of each strut, which are robotically arranged in place, baked in an oven until stiffened, and finally assembled into stretched extension assemblies. When erected into the final spherical shape for the pavilion, an ETFE polymer secondary shell is added on top for protection from the elements.

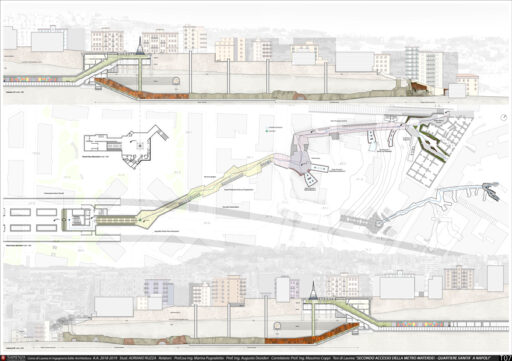

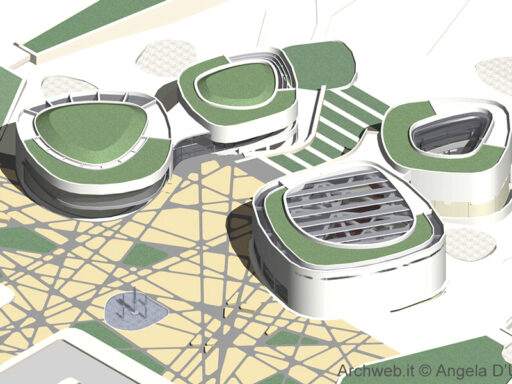

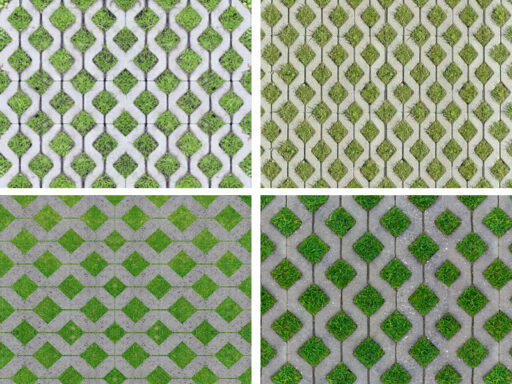

Dimostratore CRC1244 – Institute for Lightweight Structures and Conceptual Design

Research in the field of building construction is also taking place in Germany, where Dr. Walter Haase, CEO of the Collaborative Research Center (CRC1244) at the Institute for Lightweight Structures and Conceptual Design (ILEK) in Stuttgart, it is really going further.

Fourteen university research teams are working to develop ways for “create more living space with less material” using fabric facades and building elements to drive innovation in overall building design. The group is currently building a more than 36-meter experimental modular tower that will serve as a test site for new fabric-based facades and building technologies that could transform the way buildings are designed, manufactured, used and even recycled.

The simple steel post and concrete tower exist to test new materials for each of its form levels, with a specific focus on folded surface structures, innovative processing of conventional fabrics, geometrically deformable structures, and foldable origami-inspired structures that can be used to create lightweight sandwich panels. The tower was designed with flexibility in mind, so that fabric-based facades developed by academic and industrial project partners can be tested and replaced as needed in the coming years.

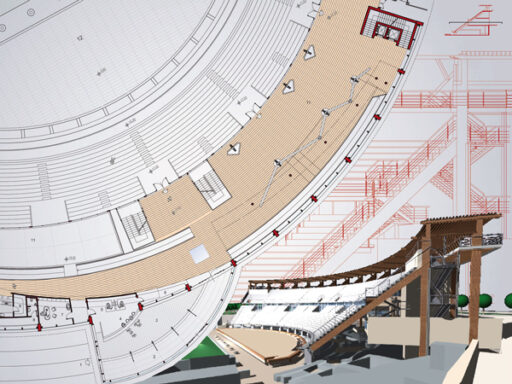

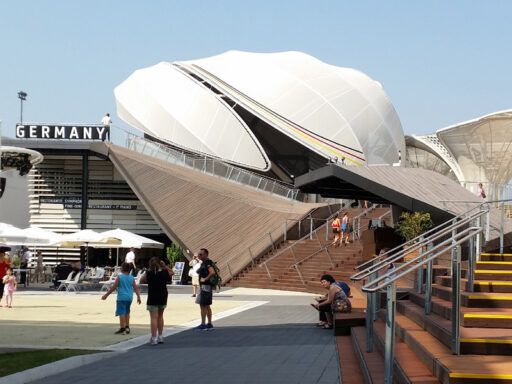

Allianz Field – Populous Architects

In terms of real-world applications, fabric-based architectural strategies are also focusing on lighting, especially in the world of sports facility design, where membrane materials such as PTFE and other custom fabrics are used to easily wrap around wide and often curvilinear.

The Populous-designed Allianz Field football stadium in Minneapolis, for example, features a clear laminated custom PTFE fabric facade created in collaboration with manufacturer Walter P Moore specifically for this project. Spread over a parametric design steel ribbed substructure, the fabric facade is backlit with 1,700 emotional LED lights that can be programmed to shine on various occasions.

Populous is also the head of the Daily’s Place Amphitheater and Flex Field project in Jacksonville, Florida, a unique dual-use space that fuses a performance amphitheater with a practice soccer field. The fabric roof panels hang from steel trusses that frame the space. The external steel structure allows for a monolithic fabric ceiling that can be bathed in LED light.

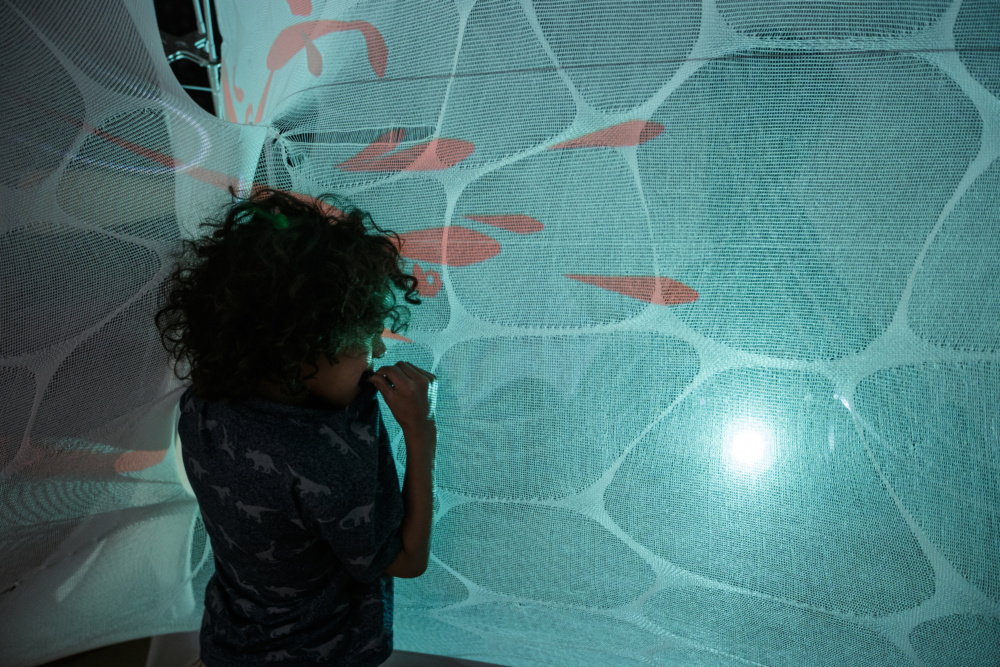

Social sensory architectures – Lab for Material Architectures

At the University of Michigan A. Alfred Taubman School of Architecture and Urban Planning, for example, Sean Ahlquist is working across disciplines and with industrial and corporate partners to develop articulated material structures and design approaches that “enable the study of spatial and human interaction. “Ahlquist’s research focuses on using computational design and fabrication to create structures and spaces that” go beyond materialization “to focus on” sensing, feedback and engagement as critical factors in design exploration, “according to a recent academic article written by him.

Using numerically controlled knitting, hybrid yarns and other digital manufacturing techniques, Ahlquist’s research team is able to generate lightweight prestressed structures, innovations in fabric-reinforced composites for aerospace and automotive design, as well as tactile sensory environments that can act as “interfaces for physical interaction.”

A recent project for the Columbus exhibition in Columbus, Indiana, creates customized textile micro-architectures by manipulating fibers and stitches to generate “instrumental, simultaneous structural, spatial and sensory qualities” in fabric structures that can be used by children with autism to filter and manage multiple sensory inputs.

The article has been translated into Italian from the original “Fabrics could be the next big thing in facades” by Antonio Pacheco on The Architect’s Newspaper