Glass in architecture

Historical notes - Technology - Type of curtain walls

Glass: historical notes

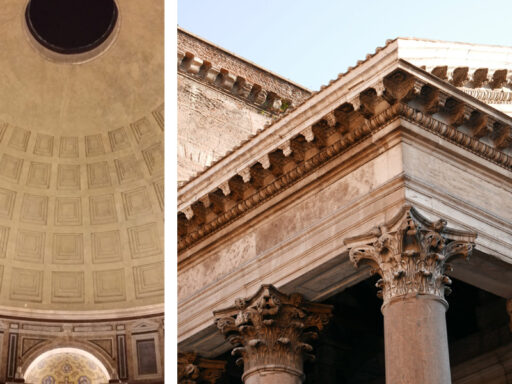

The history of glass dates back to the most remote times. In fact, this wonderful material has rather ancient origins, dating back to several centuries before the birth of Christ. The first to contribute to the processing of glass and consequently to the birth of the first glass industry were the Romans, around 100 BC. C. Subsequently, Murano and Venice were for a long time the center of attention for what concerns the glass art; in fact, they still represent a point of reference in this area today. Murano stands out above all for the composition of a glass which was called “Crystal” due to its extreme perfection and clarity.

From a technical point of view, glass manufacturing requires three fundamental elements:

- vitrifying (silica);

- fondant (soda or potash in the form of sulfate or carbonate);

- stabilizer (lime in the form of carbonate).

Since the 1950s, the most produced glass has been FLOAT GLASS: it is a versatile and easy to model product, the most used in industry, construction and architecture. Furthermore, based on the metal compounds used, glass is able to take on the desired color (blue, green, yellow, etc …) In the architectural field, glass began to be used in the 1800s, becoming the protagonist in 1900. At that juncture of time, Float is the main product, from which the different processes arise.

Glass technology

Before understanding the various creations deriving from this material, it is first of all good to understand which types we are dealing with:

- Float glass: it is the basic or starting product, it is transparent and therefore suitable for processing multiple categories.

- Laminated glass: consists of two or more plates connected to plastic films. This is an excellent safety factor, in fact in case of breakage the splinters will stick to the film, avoiding any damage. This type of glass is used for several purposes. For example, a good amount of PVB is able to improve the acoustic conditions, or thanks to its resistance it is a valid product against theft or accidents.

- Selective glass: it is of the Float type with the addition of deposits and / or metal oxides, this serves to optimize the thermal insulation, while still guaranteeing an excellent passage of light. This typology is used in the design of curtain walls.

- Insulating glass: also known as “double glazing”, it consists of at least two sheets of glass divided by a gap of dry air or gas and an aluminum spacer that acts as a powerful thermal insulation. Depending on the treatment, this particular type of glass can be used for multiple purposes.

For what concerns the main processing methods, it is possible to describe:

- Tempering: this is the so-called “tempered glass”, modeled inside a specific oven through the tempering process, which is none other than the propensity to increase the mechanical resistance of the sheet. In this way we will have a product that is far (at least 5 times more) more resistant than classic glass. One of the characteristics deriving from this technique is that in the event of breakage, the glass is divided into very small fragments, reducing the resulting risks. These products can show mini deformations, which however are completely natural, as they derive from the production process.

- Grinding: is the control of the edges of a glass plate and can take place in two ways. The first is called polished edge (smooth and beveled edge at 45 °) and the second with raw edge (opaque and wrinkled edge always at 45 °).

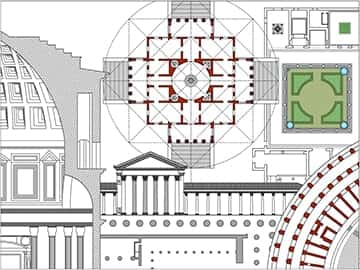

Glass in architecture

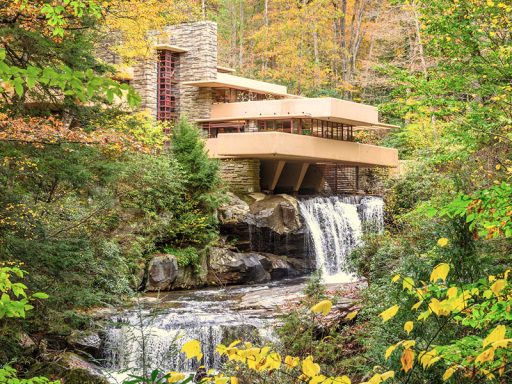

Glass in architecture (and not) is used for multiple purposes, such as the ornamental ones given by furniture design (table, display cases, shelves, etc. …), doors with an innovative and classy aesthetic or even stairs and walls. In short, everything related to interiors and exteriors can be achieved through the use of this material. Transparent, opaque or translucent: glass responds perfectly to the needs in terms of renovation or construction.

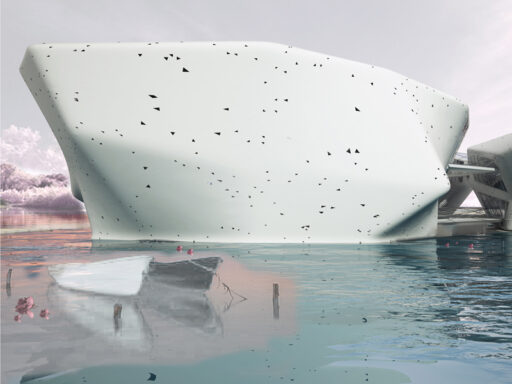

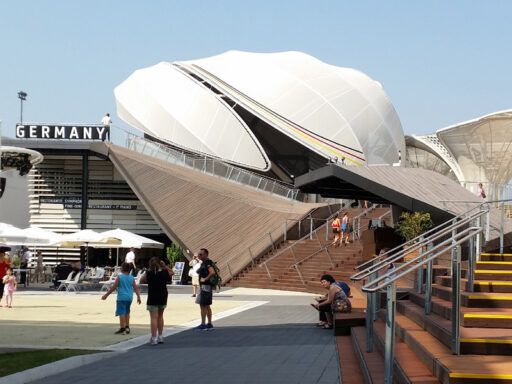

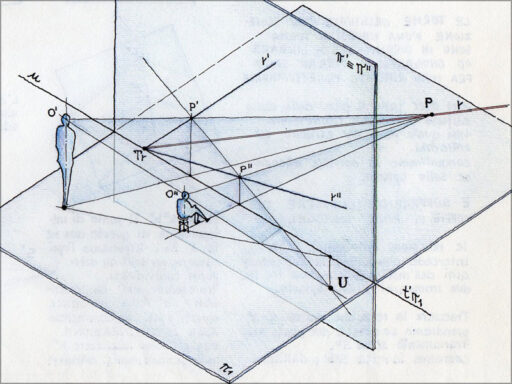

The transparent architecture, through the innovative technologies of glass, is able to give light to contemporary and first-class works. Therefore, the visual level is added to the performance level of the materials, synonymous with class and elegance.

A good example is given by the glass facades, of quality and refined and elegant design.

The glass is able to “filter” the light making the environment favorable, creating a situation of comfort for every need. The design of the windows must take place according to well-defined criteria, with a preference for attention to the smallest details. In this way, you will be able to fully benefit from the potential of the product. As regards this category, the possibility of choice is very wide. In fact, there are several solutions aimed at energy saving, latest generation glass facades that act as powerful thermal insulation or quality materials resistant to scratches and humidity, both with satin and glossy surfaces. In modern architecture, glass is one of the undisputed protagonists and is in first place in the choice of acoustic and thermal protection. The use of glass in construction is also governed by a series of rules, which vary according to the design.

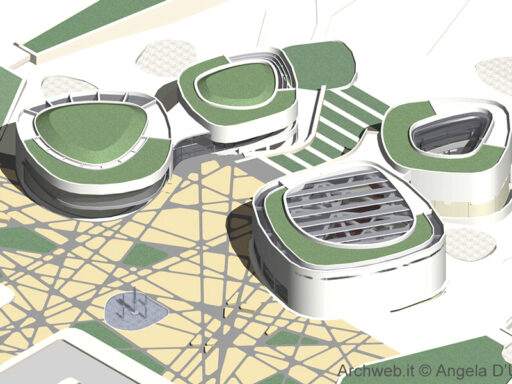

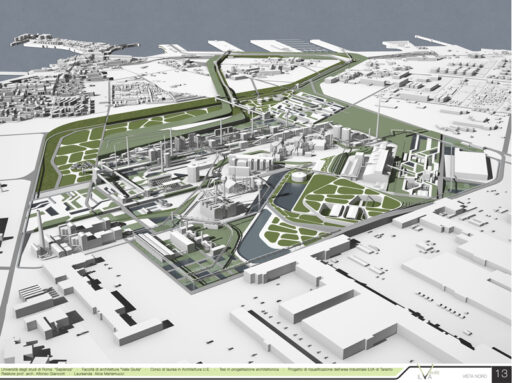

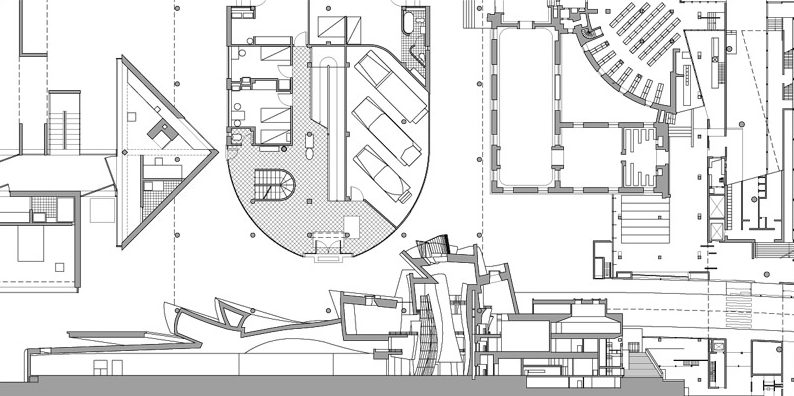

The curtain wall, also called “Curtain wall“, is very common in contemporary architecture for the creation of buildings for both residential and commercial purposes. Its origins date back to 1925, in the course of rationalist architecture, derived from the need to be able to enjoy more natural light. Thus an innovative structure was born, consisting of metal uprights and transversals, associated with transparent glass plates with windows.

Main types of curtain walls

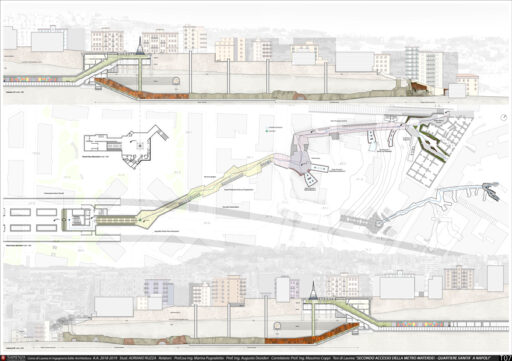

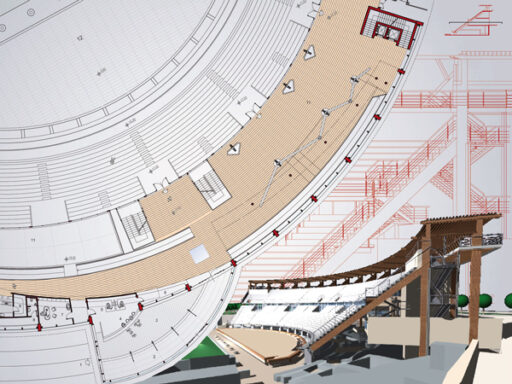

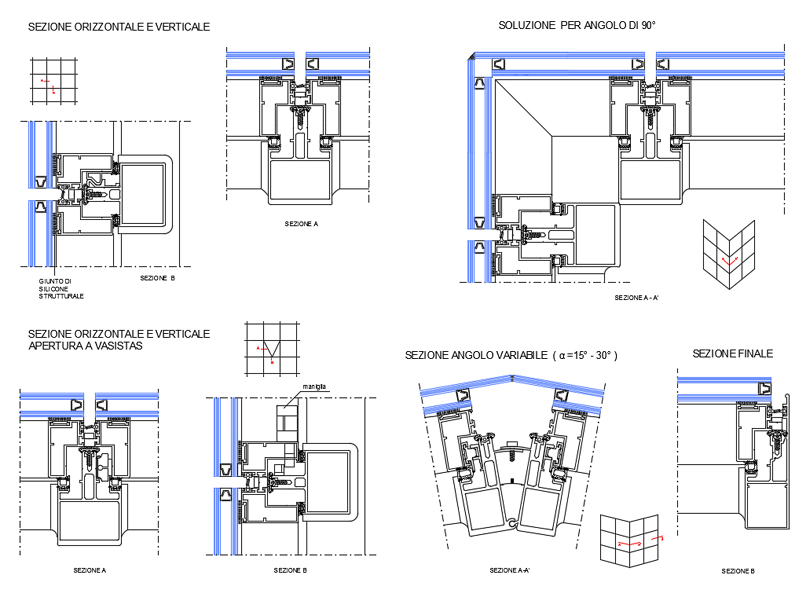

- Structural and semi-structural facades: these are continuous glazing with a minimal design. The load-bearing structure is located behind the curtain wall and between the glass plates there are structural adhesives as a support. The thin joint that is created is easily sealed with special gaskets or silicone.

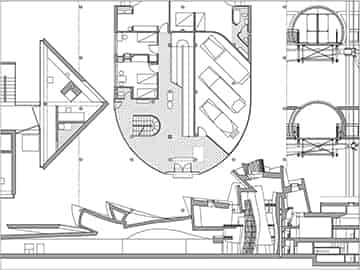

- Facades with mullions and transoms (dwg): they are the evolution of the very first Curtain walls, in fact, they consist of a network of vertical mullions (main structure) and horizontal transoms (secondary frame). The effect can be defined as “knit” and is precise and defined. The fixing is done by means of specific adjustable brackets to make the alignment perfect. As for the infill, it usually takes place via double glazing or opaque panels. The “double glazing” feature guarantees the protection of privacy, in fact, it is possible to observe the environment surrounding the building from the inside but not vice versa. It is also possible to insert different types of windows. The cross-pillar facades are often used for the lighting of stairwells, especially in very high buildings.

- Cell facades: they are made in factories, which is why they represent high quality products. The advantages deriving from the installation of cell facades are the reduction of costs and labor. The fixing can be by bonding with silicone or mechanical.

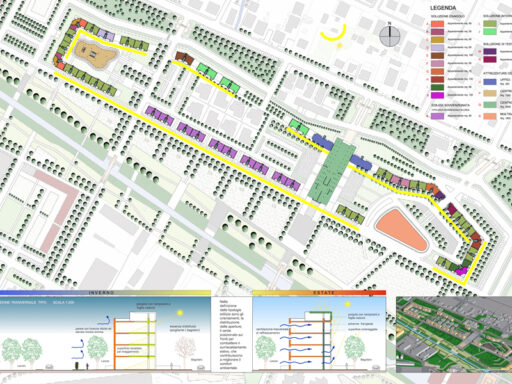

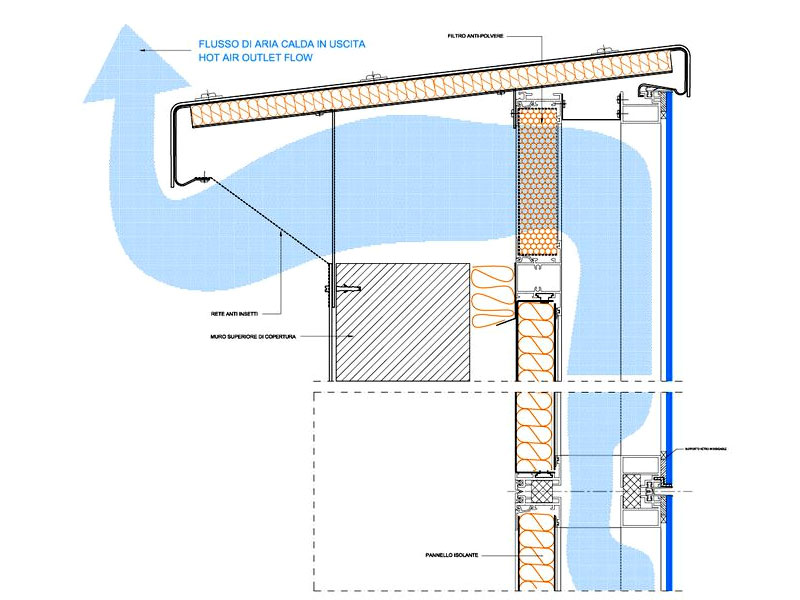

- Ventilated facades (dwg): they are chosen to increase the comfort of the environment and promote energy saving. A ventilated cavity is created between the facade and the cladding, with a thickness corresponding to a couple of centimeters. This layer of air will allow a perfect climate in every season, this because in winter it minimizes heat loss and in summer it eliminates hot air. Generally, the support structure is in anodized or painted aluminum.

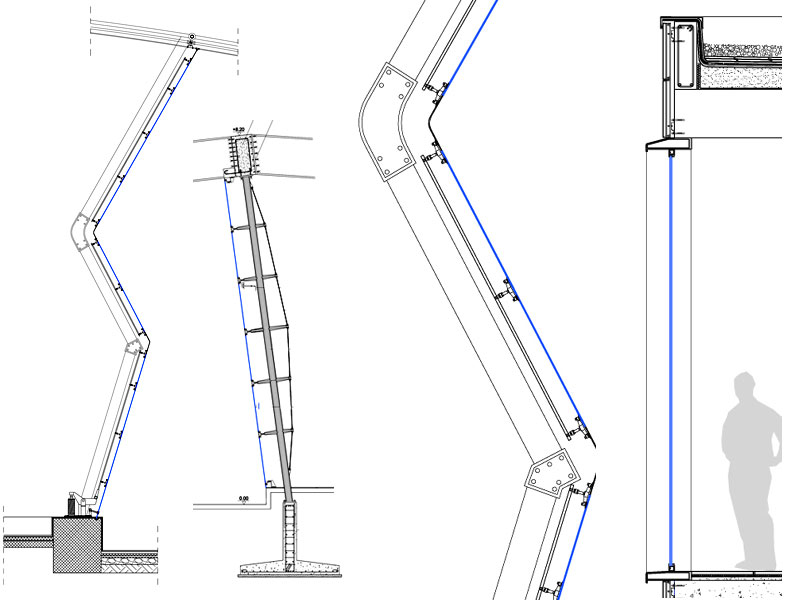

- Facades with point anchors (dwg): they differ from all other categories as the glazed part is completely separate from the support structure, however these require frequent maintenance, as the air or water seal is sealed only with silicone: they are used for minor jobs such as for example greenhouses.