Laser cutting for sheet metal

One of the techniques that has significantly expanded in the construction sector

LASER – A look at the technique

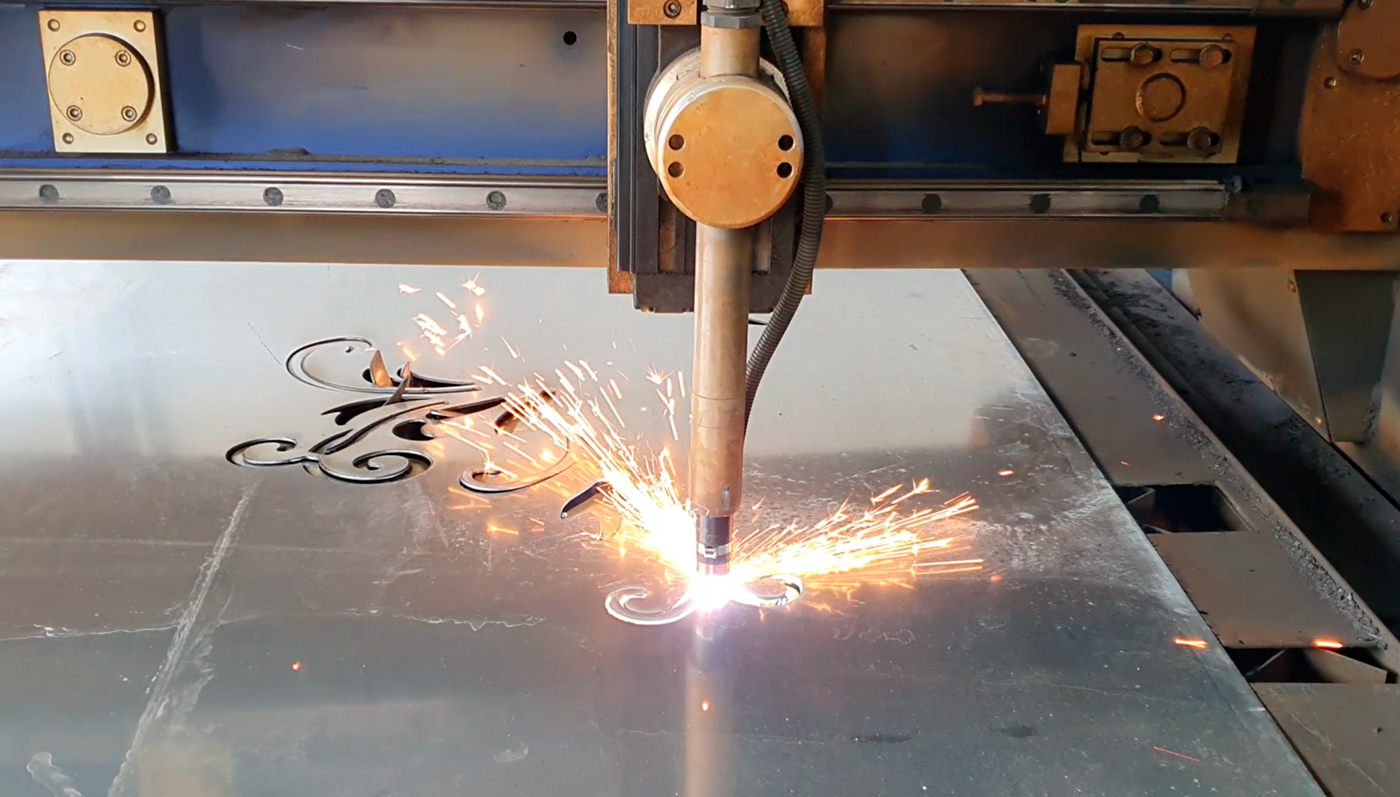

Laser cutting is one of the techniques that has spread significantly in the construction sector because it allows sheet metal to be cut very precisely and allows the creation of products with a great aesthetic effect.

LASER, acronym of “Light Amplification by Stimulated Emission of Radiation“, in Italian “Amplification of Light by Stimulated Emission of Radiation”, is the technology with which photons, particles of light, excited by the current, emit energy in the form of light . This, directed, forms a ray that produces heat capable of engraving, marking or cutting various materials. There are many types of lasers (gas, fiber, solid state, dye, diode, etc.) and the use is widespread by optical readers to read information from discs (e.g. DVDs) and bar codes, used also for surgical procedures.

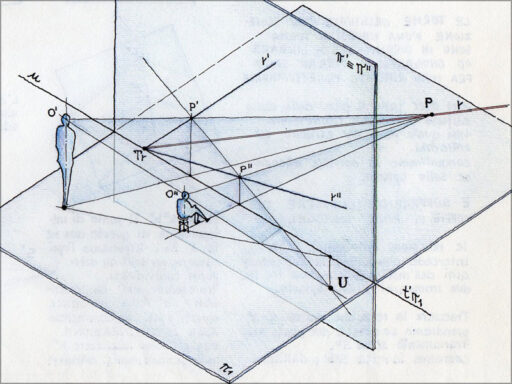

The laser beam is produced by the laser source, called “resonator”, goes into the cutting head of the machines and, through a lens, changes to reach a very high power, melting the sheet. The perfect correlation between the computer software and the mechanical arm allows to obtain very high precision levels.

Laser technology is used to cut, engrave and mark products of various materials indelibly, leaving the shape intact, smooth and without burrs. This is a great advantage because, in very small elements, infinitesimal roughness could cause damage to contiguous parts, generating tears, tears or scratches. Laser marking also allows products to be identified so that their characteristics can be traced over time. This application is widespread in various fields such as electronics (to mark connectors, relays, switches, displays, etc.), medical (managing to label very small products such as needles and various prostheses that must be smooth), aerospace, automotive.

Laser marking lasts over time and allows you to reconstruct the history of a piece used and to identify all its characteristics and the history of its production. The laser marking also has characteristics of elegance and refinement that allow you to engrave backlit keys, to sign accessories and objects, to leave markings resistant over time.

The finished products can be made without labels attached above, respecting the ISO 9000 standards and leaving the objects unaltered. The idea is that of the marking of precious metals which is applied widely, allowing laser technology to make engravings that allow precision and speed of execution, thanks to the continuous evolution that allows to obtain very high quality beams.

Laser cutting for fencing sheets, railings, gates

From engraving to cutting, everything is possible with the laser.

Over time, the technology has refined more and more and the edges of the cut sheet have finishes that, with the advancement of the laser beam, are imperceptible in thin sheets and leave “flaky” edges on larger edges, edges that must be removed first painting. The sharp edges at the exit of the laser cutting can determine the “burned” effect, due to the change of direction of the laser beam and, to avoid this, care is taken to maintain the minimum distance between the elements to be cut, in depending on the thickness of the sheet.

Laser cutting can be used on flat sheets, on bent surfaces, even on pipes or other three-dimensional elements.

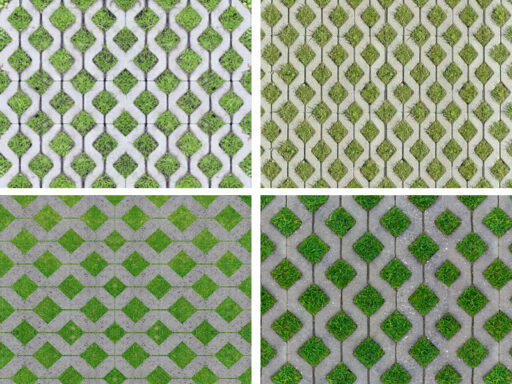

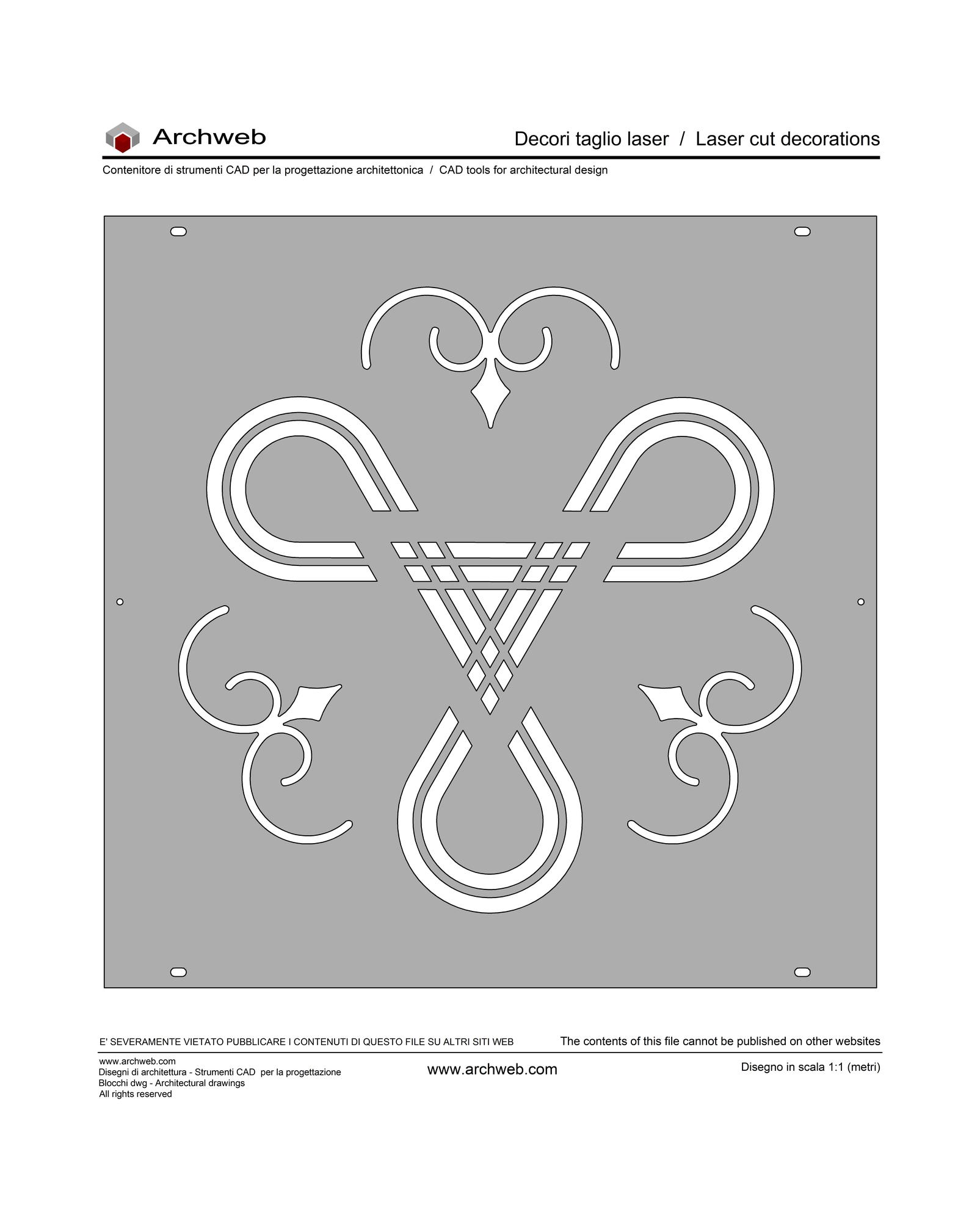

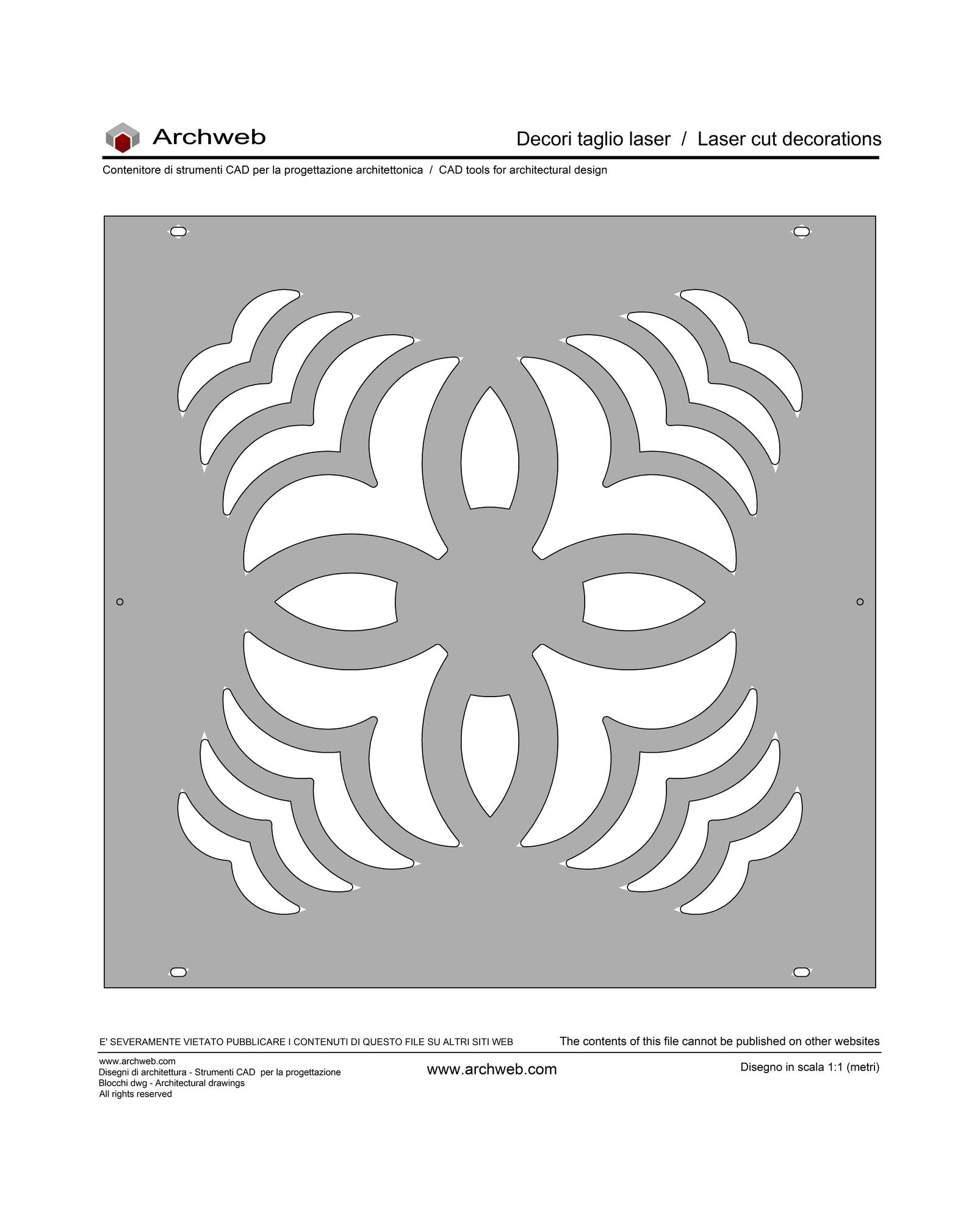

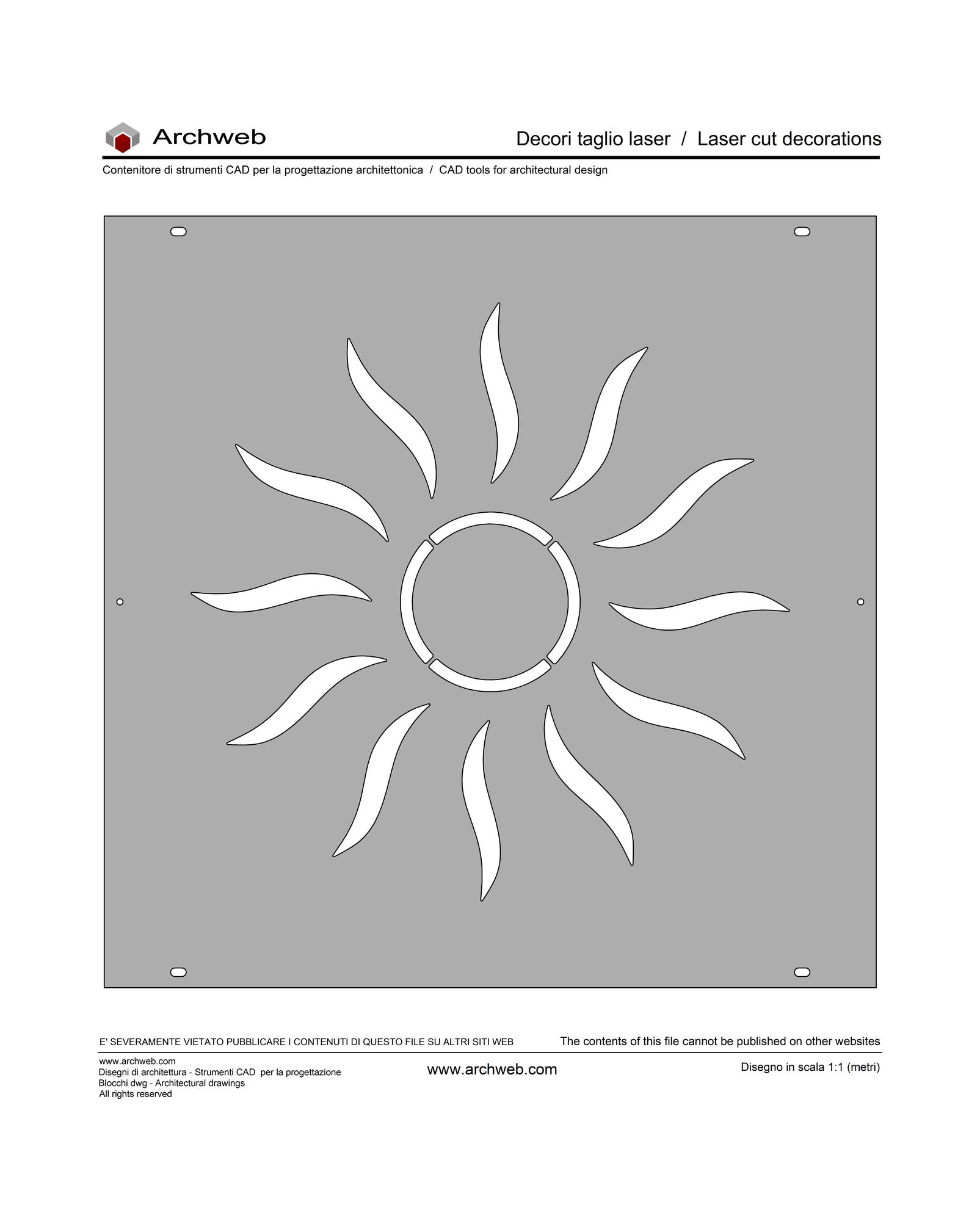

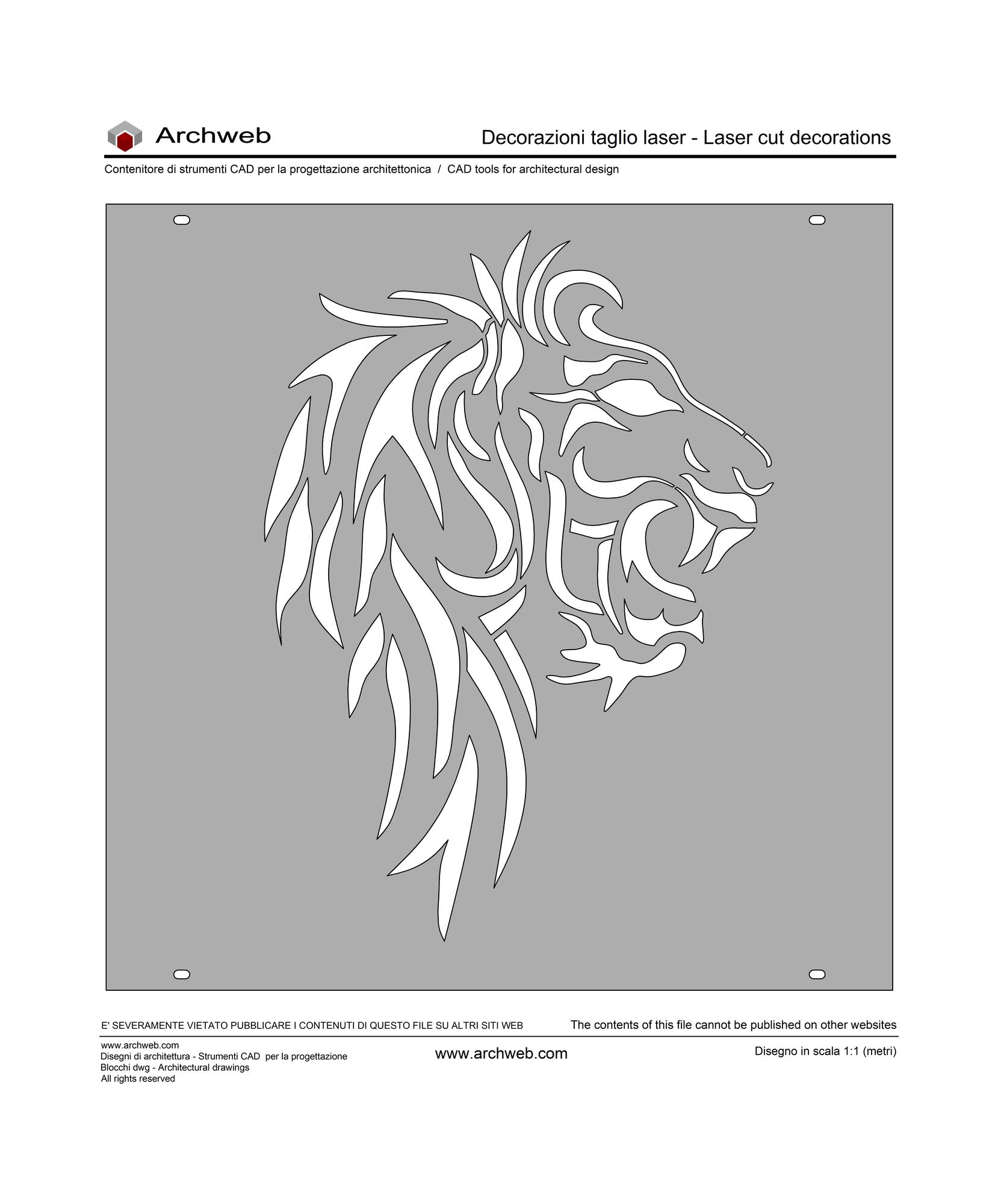

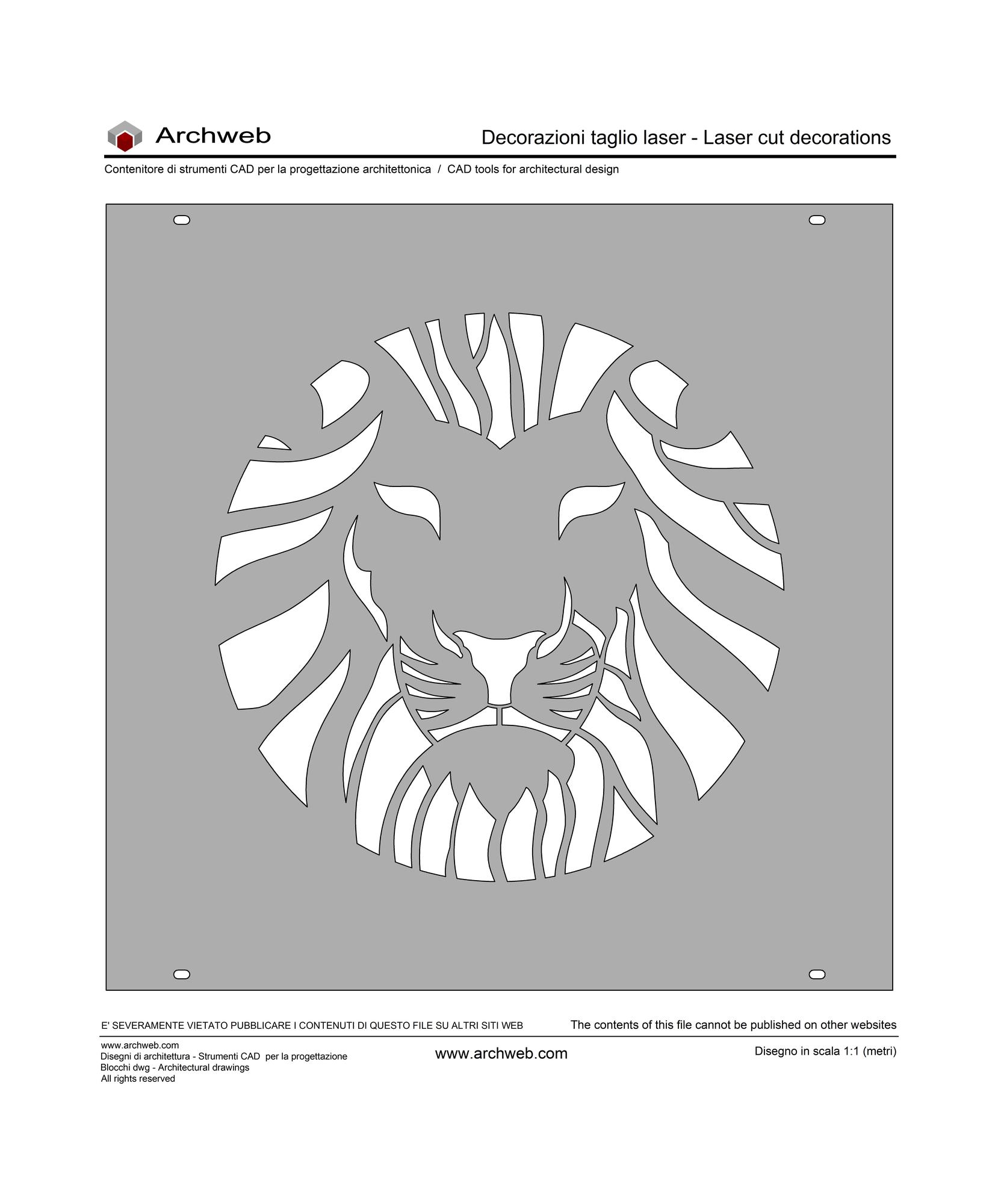

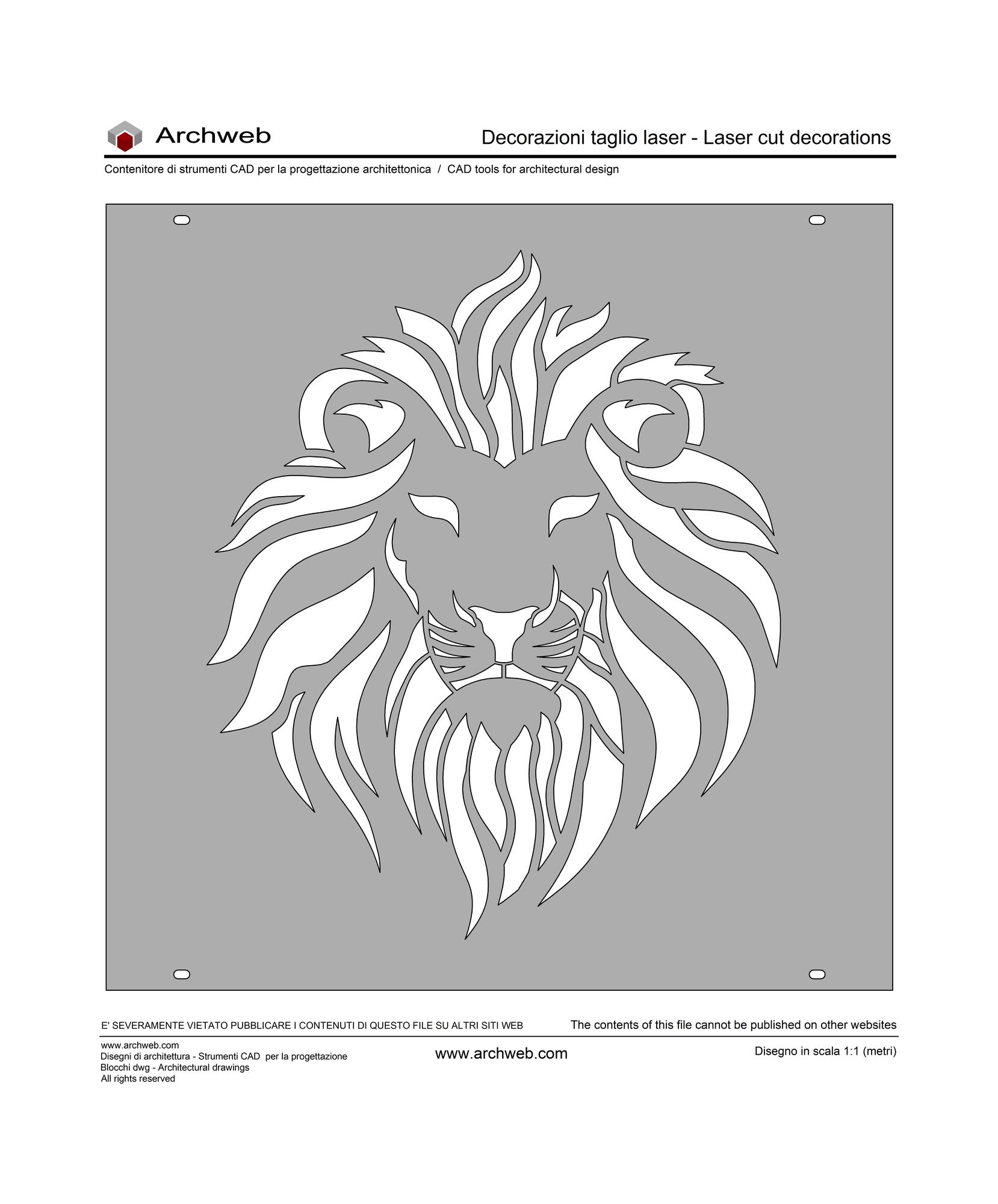

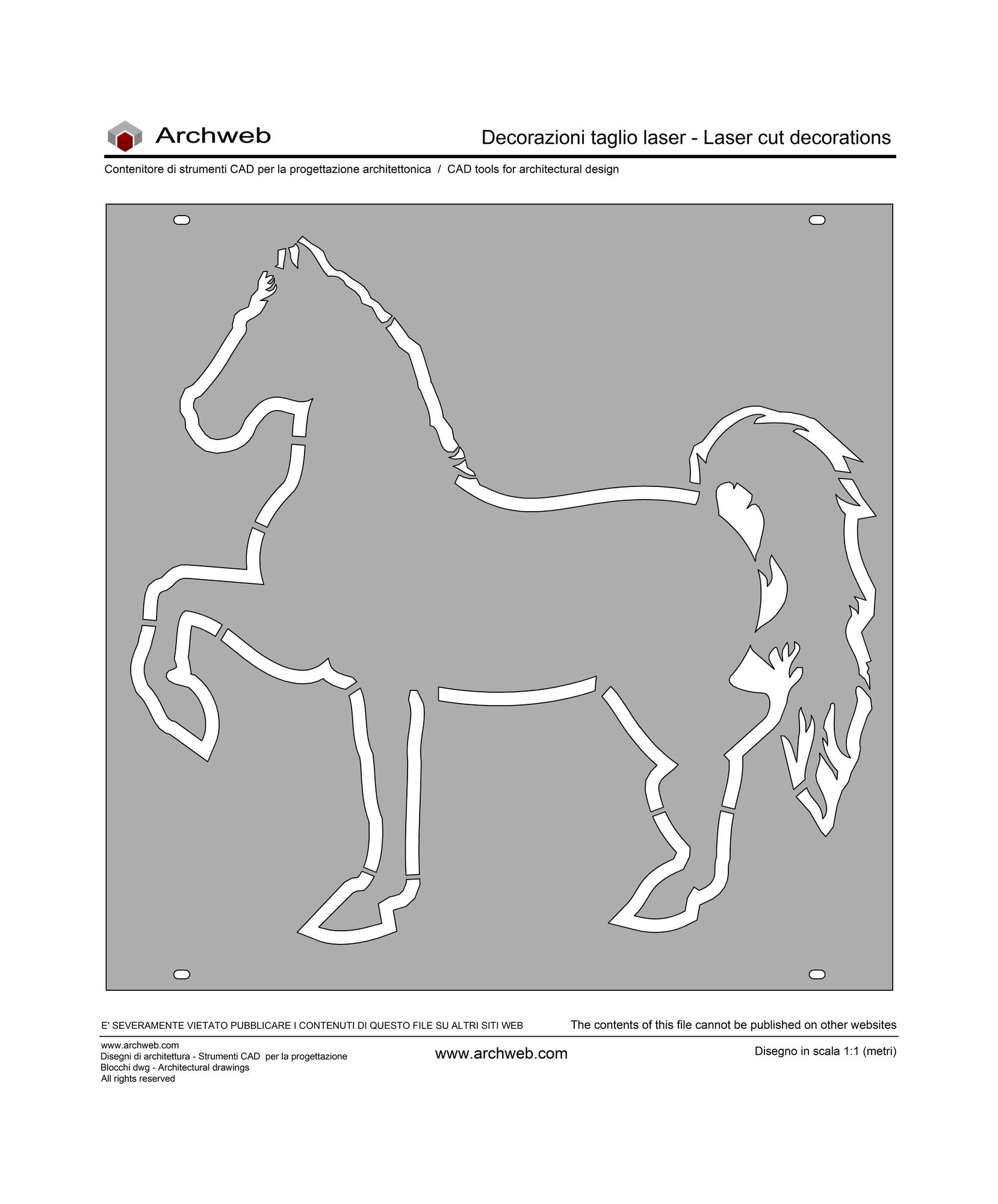

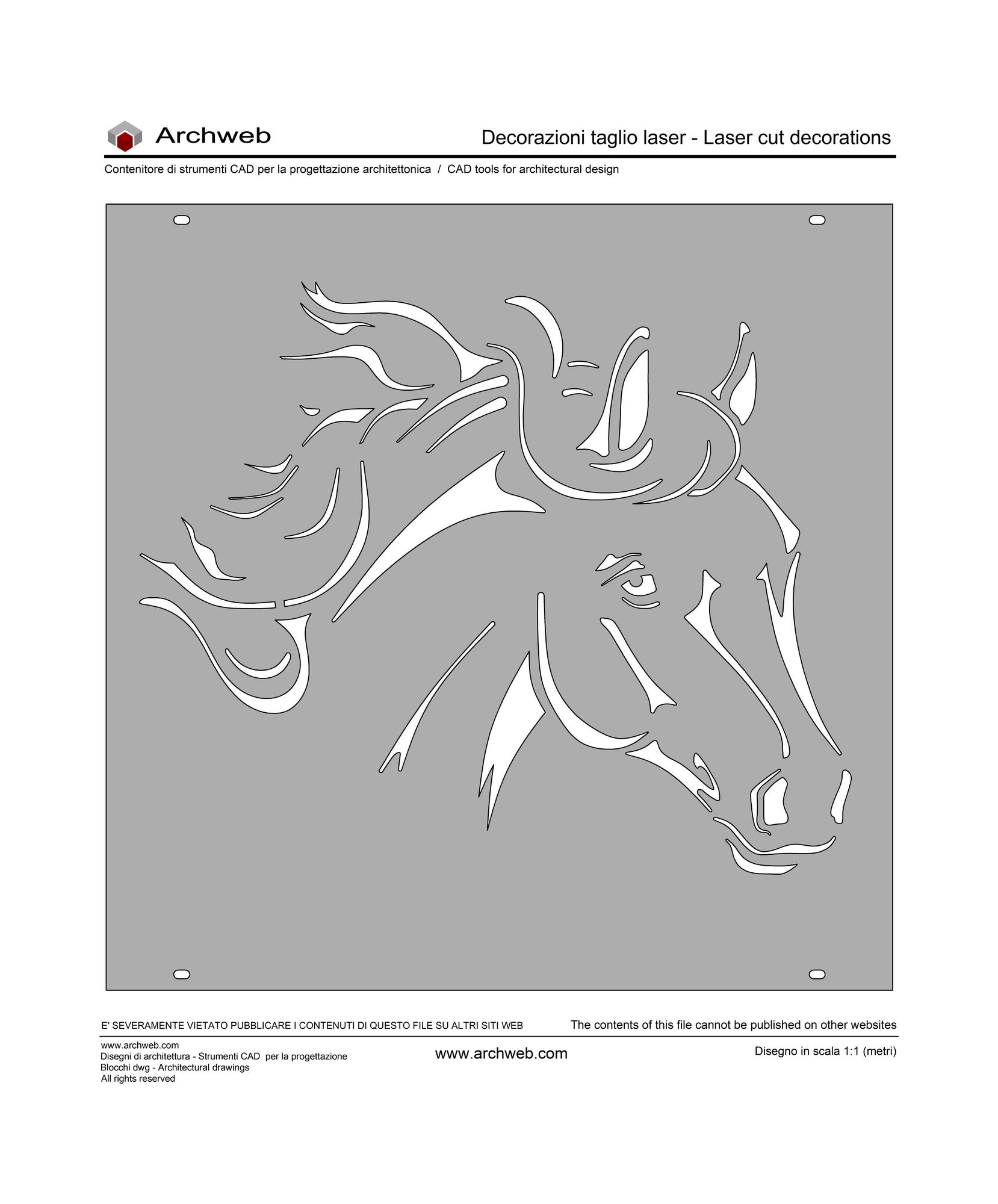

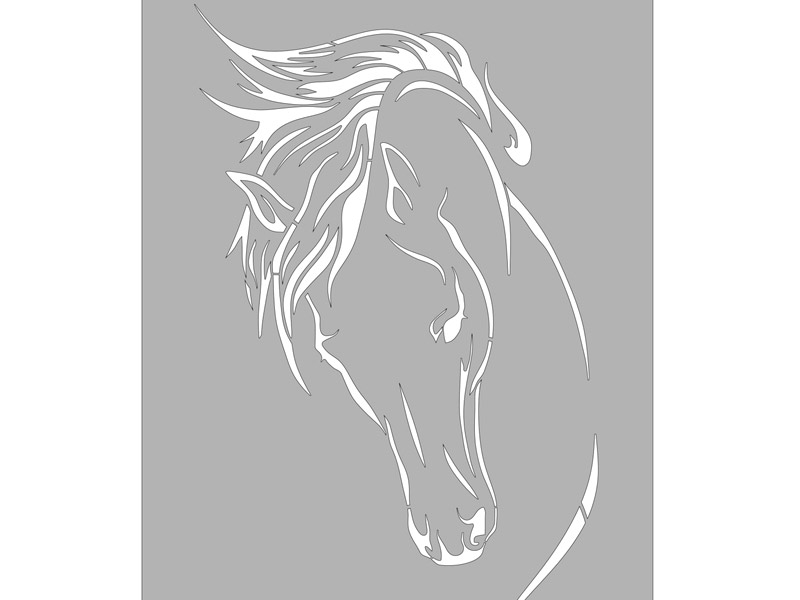

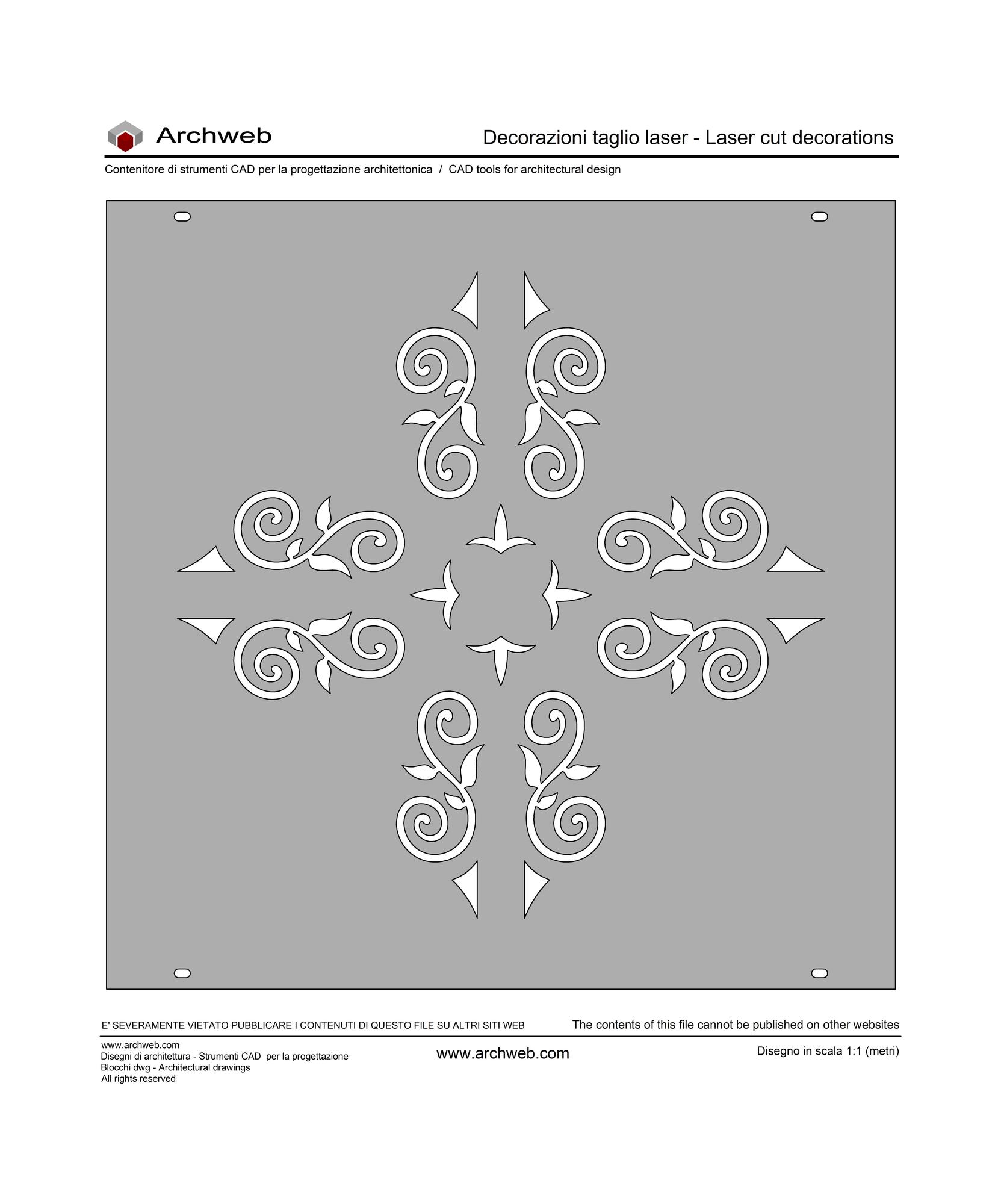

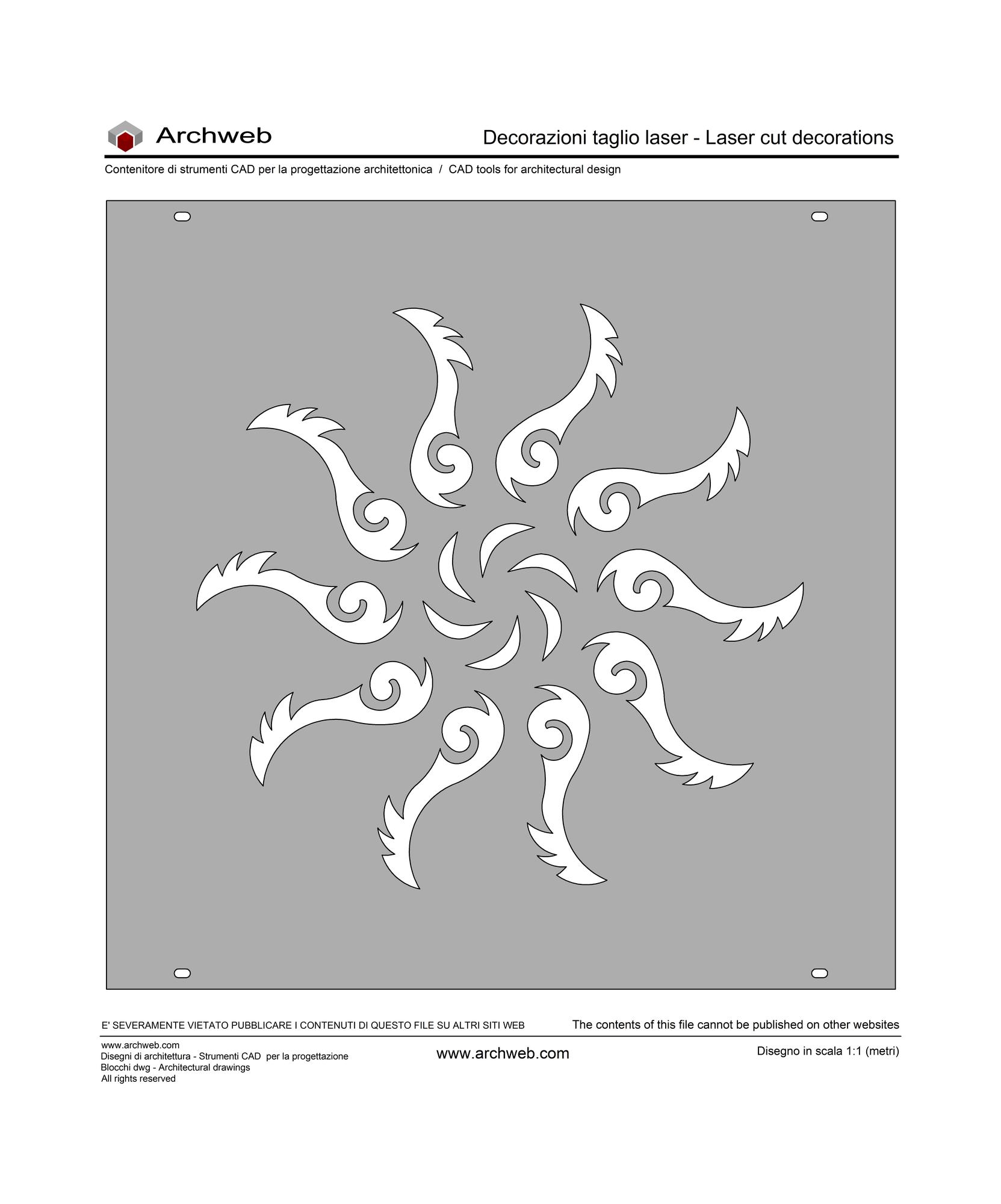

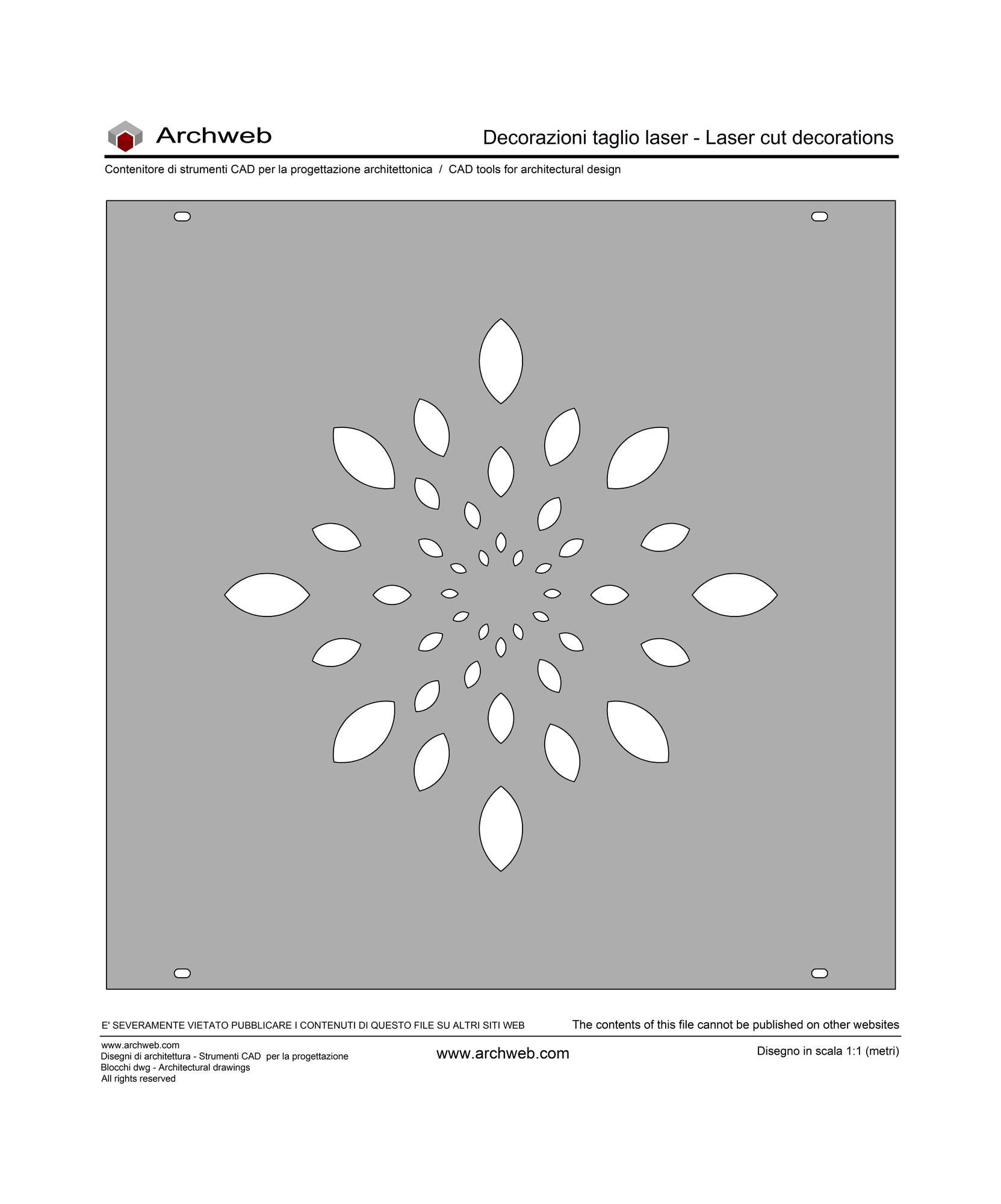

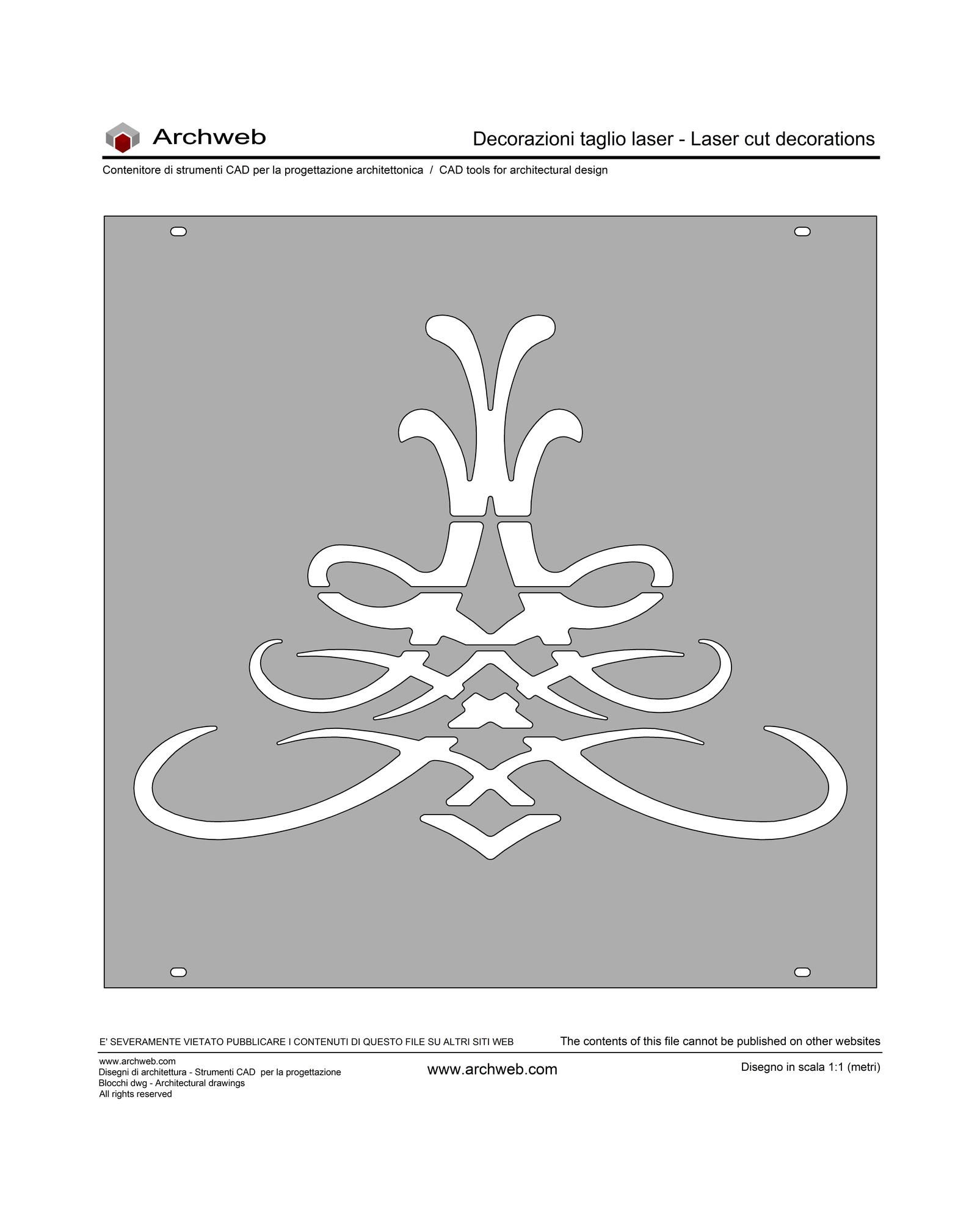

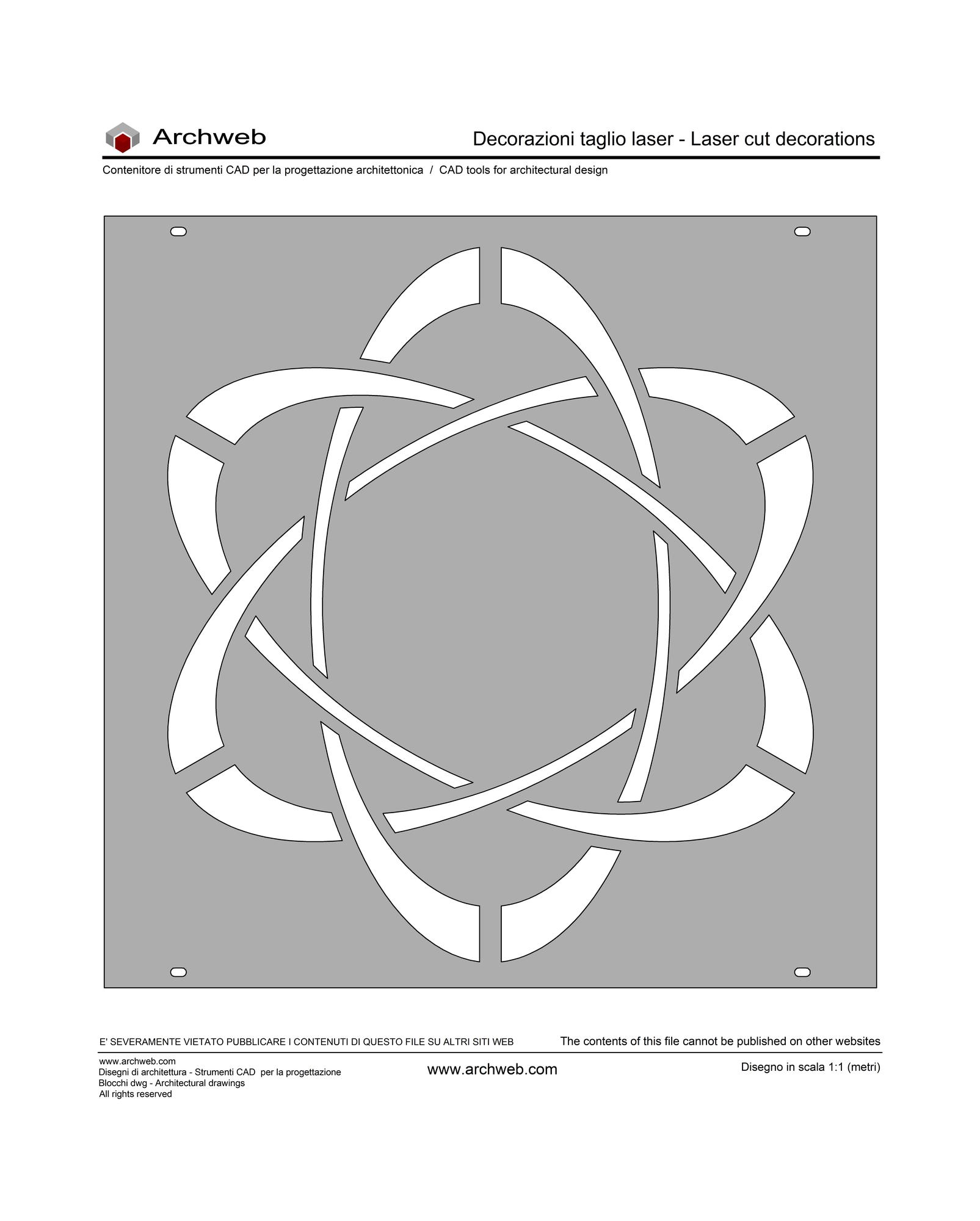

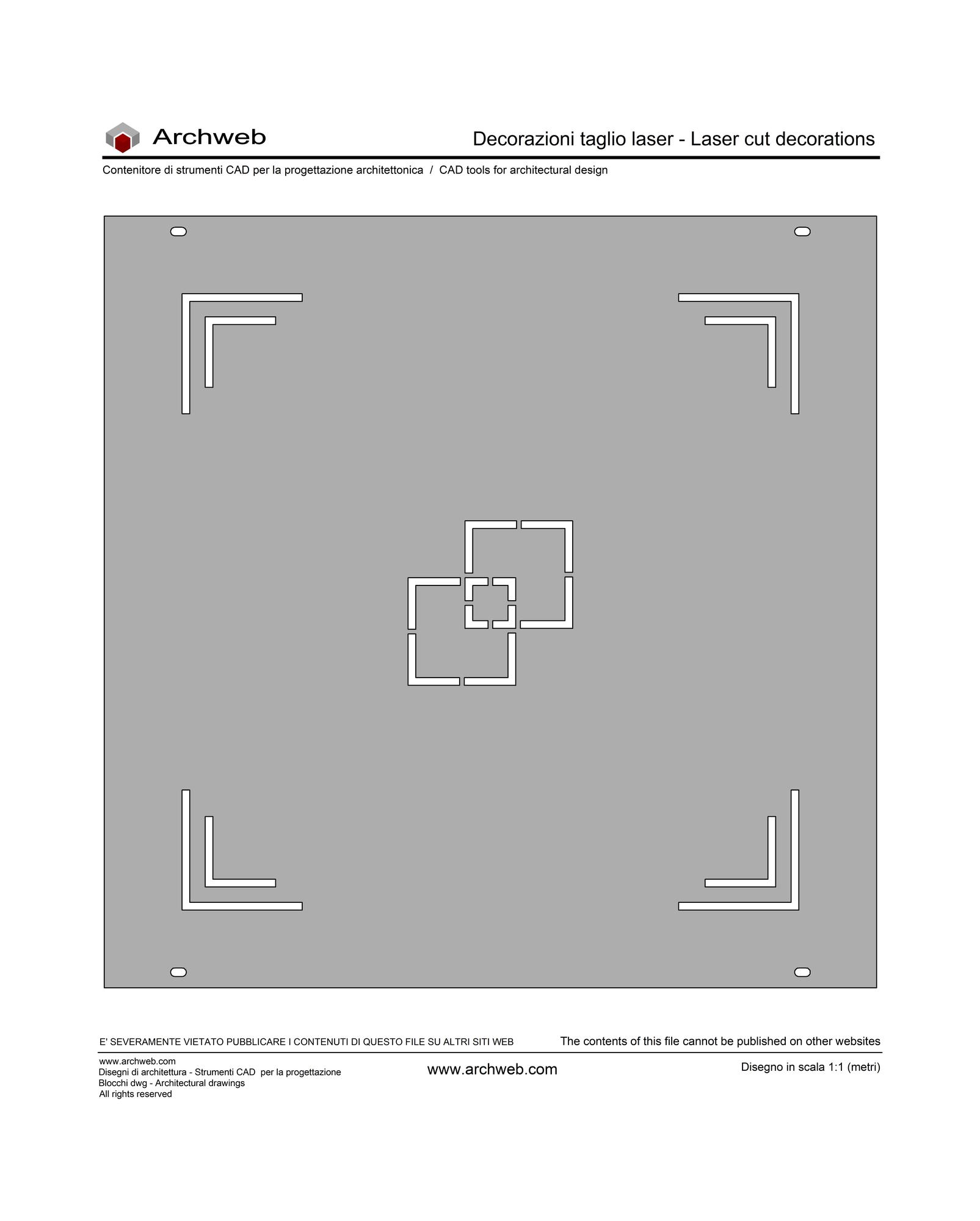

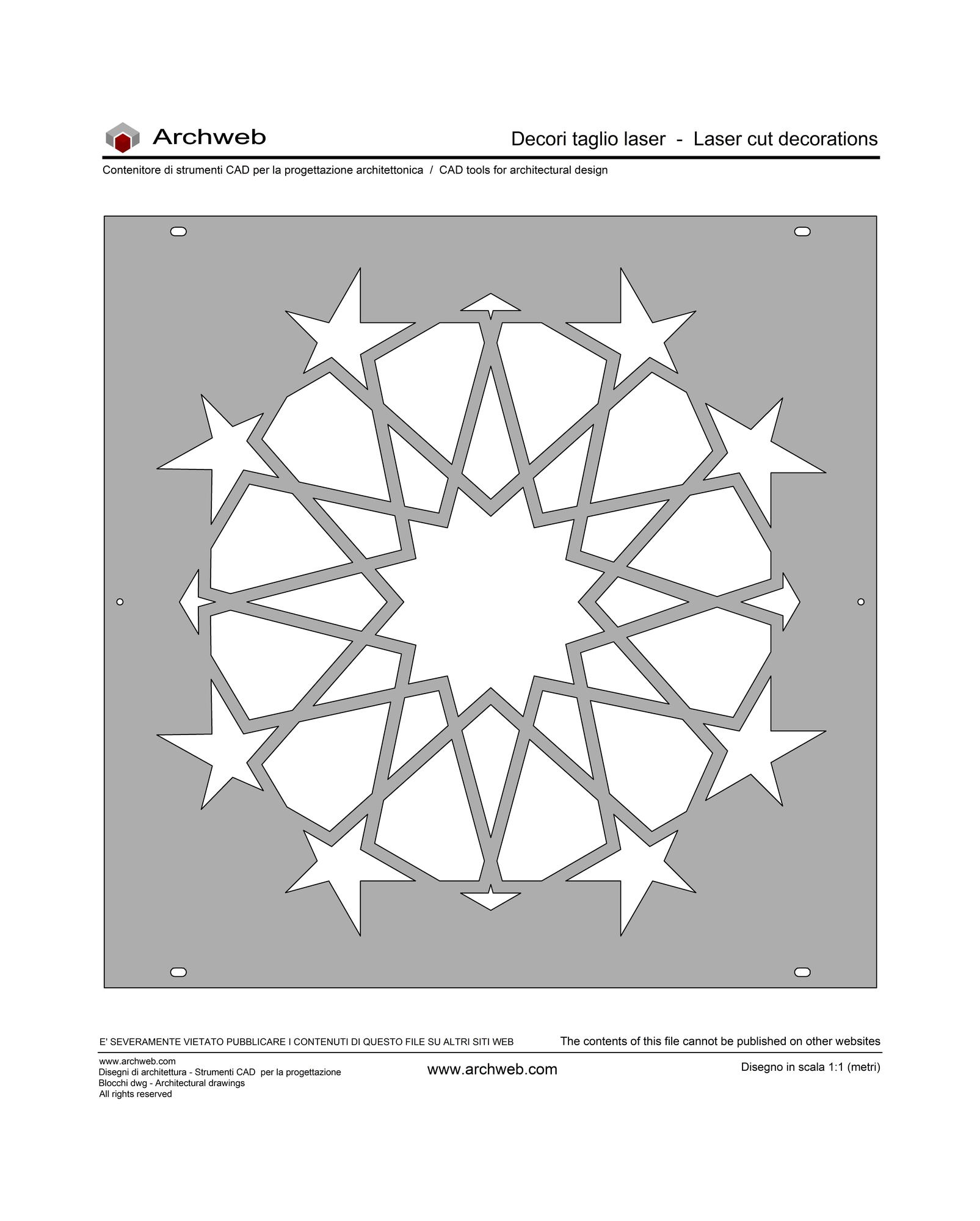

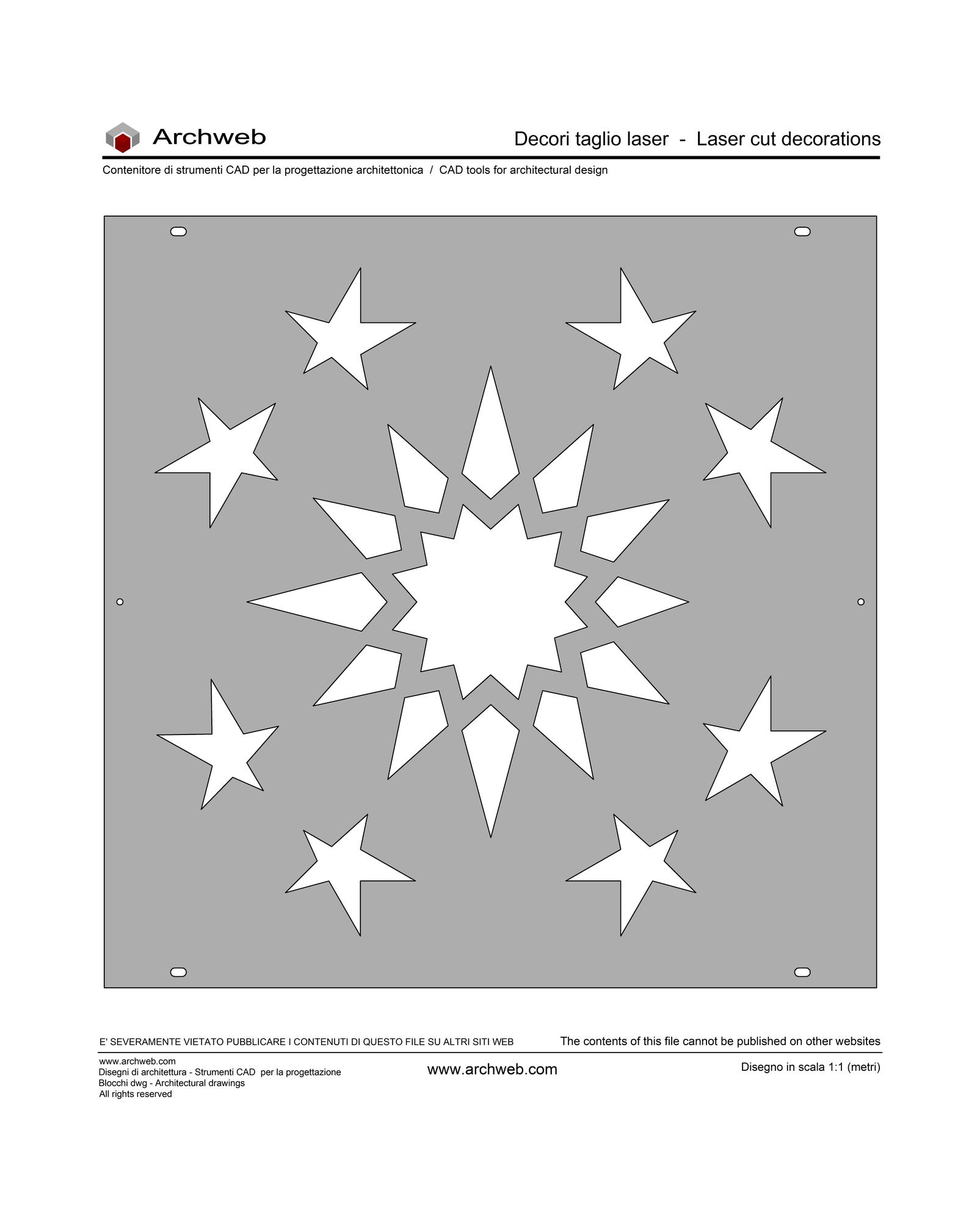

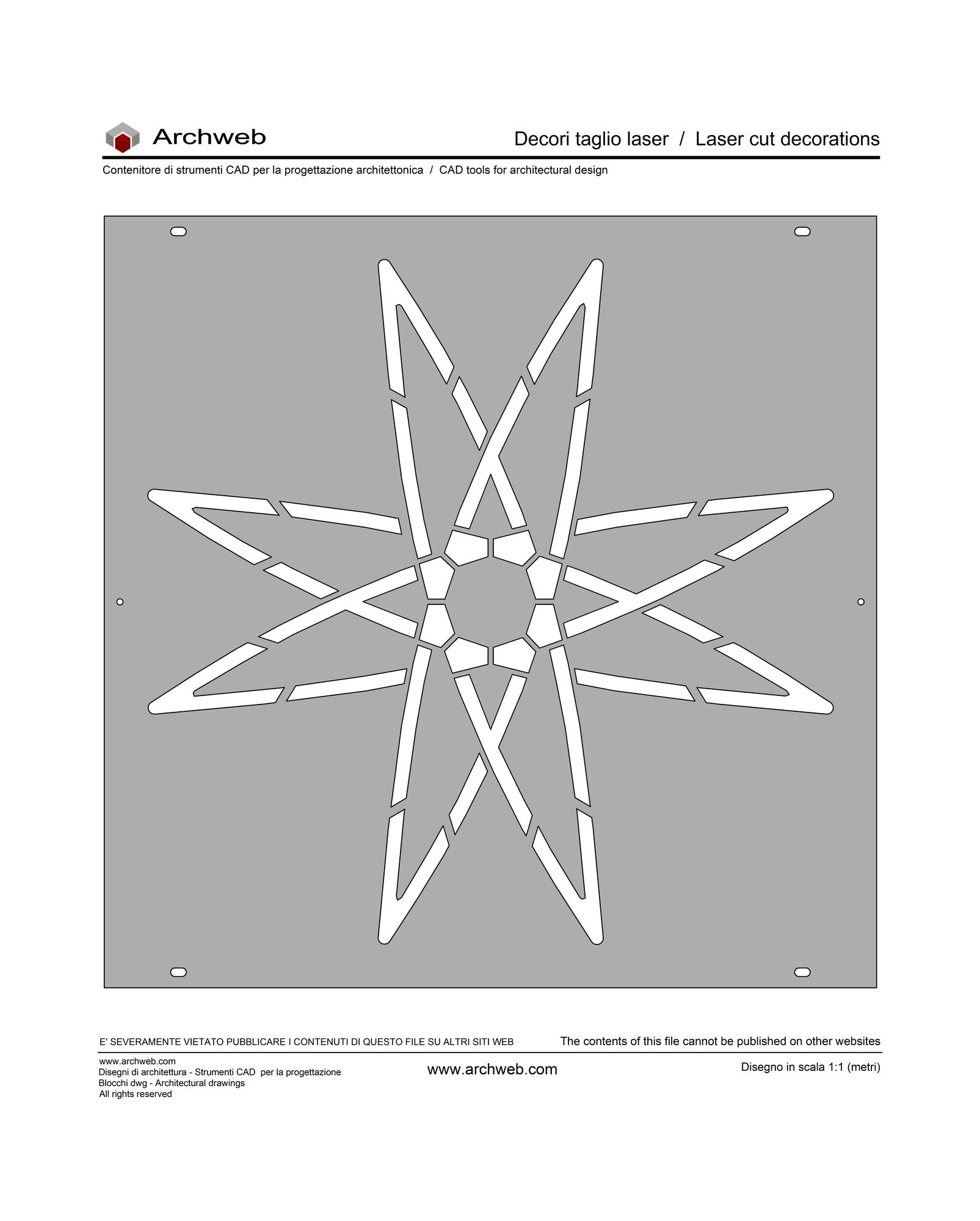

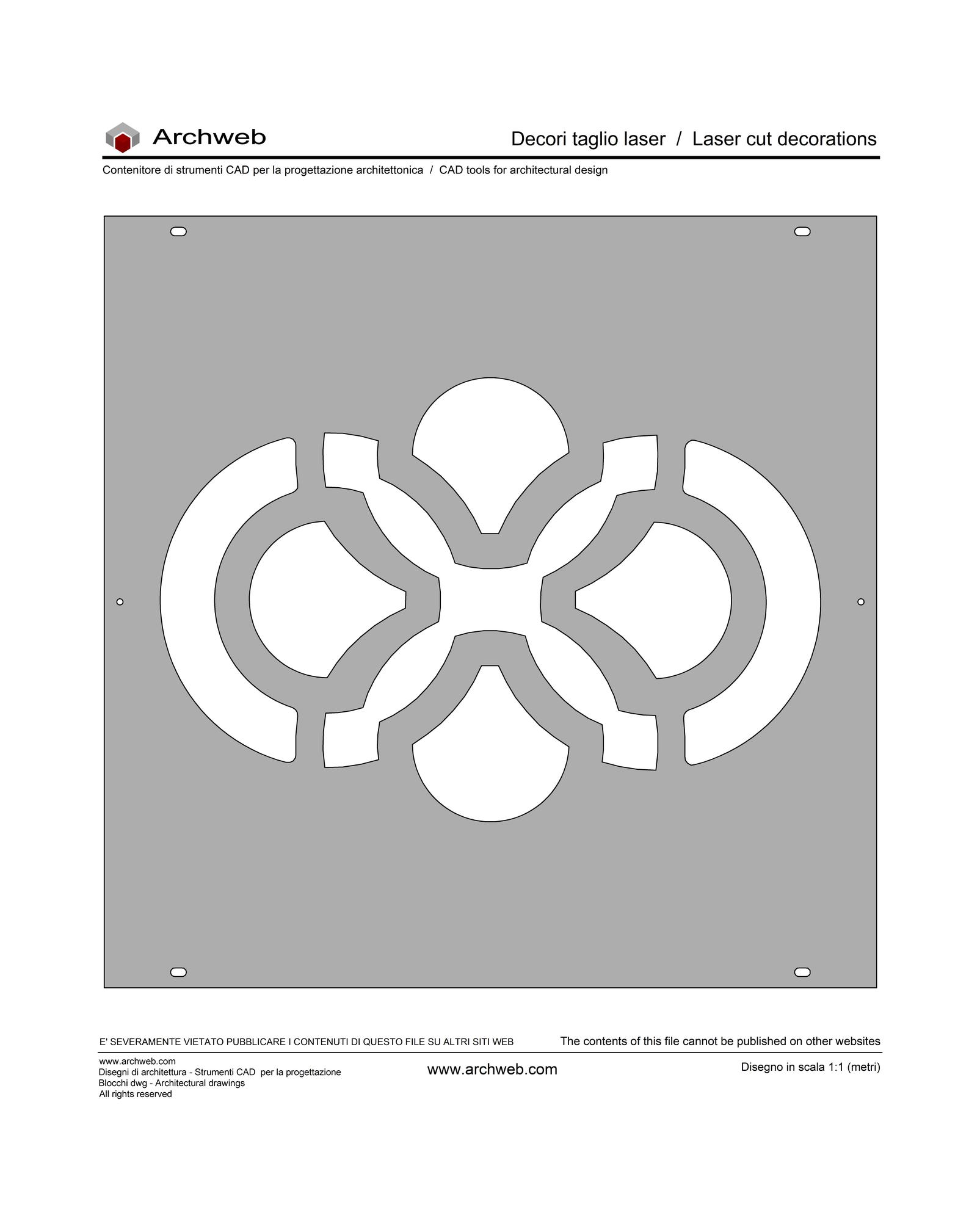

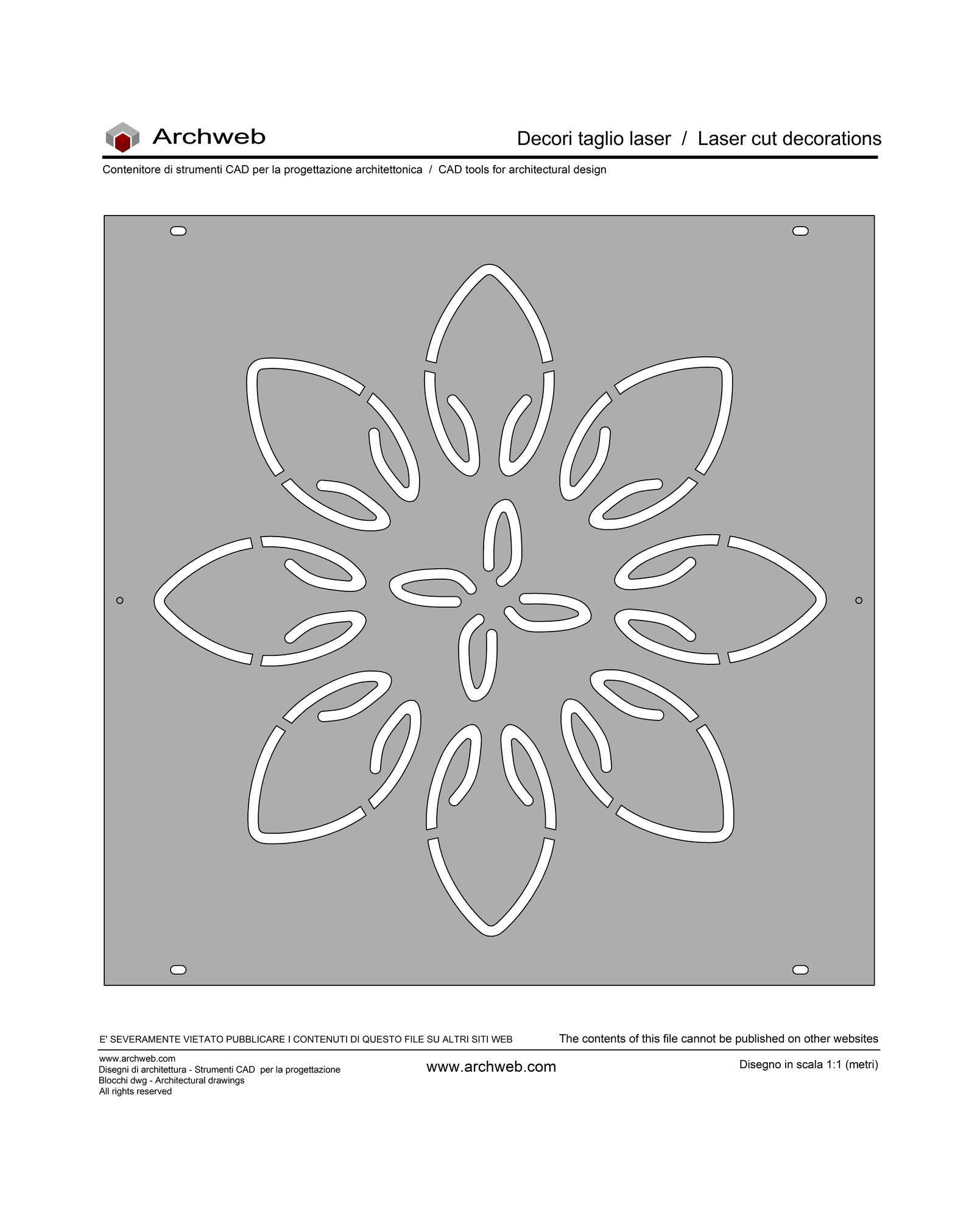

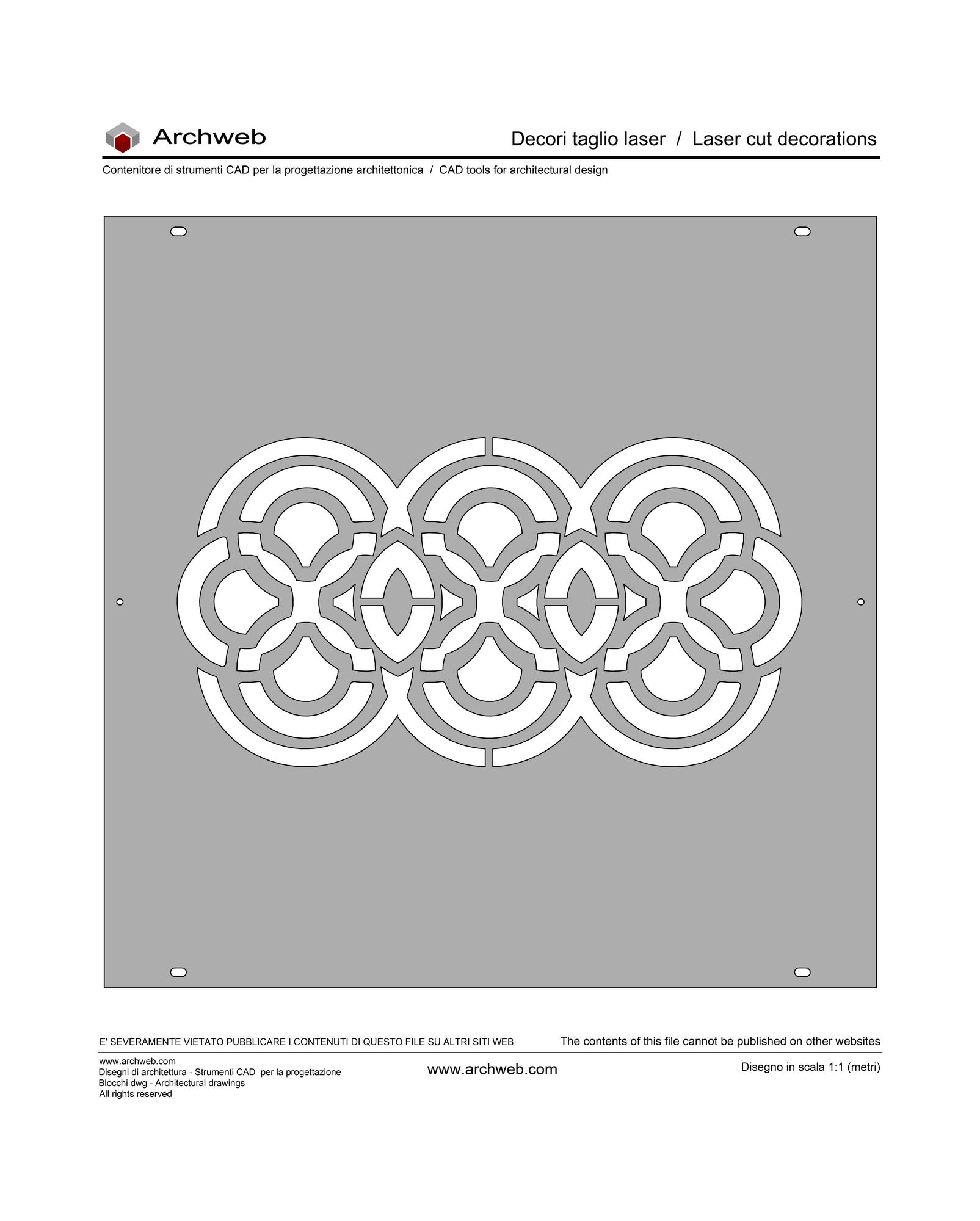

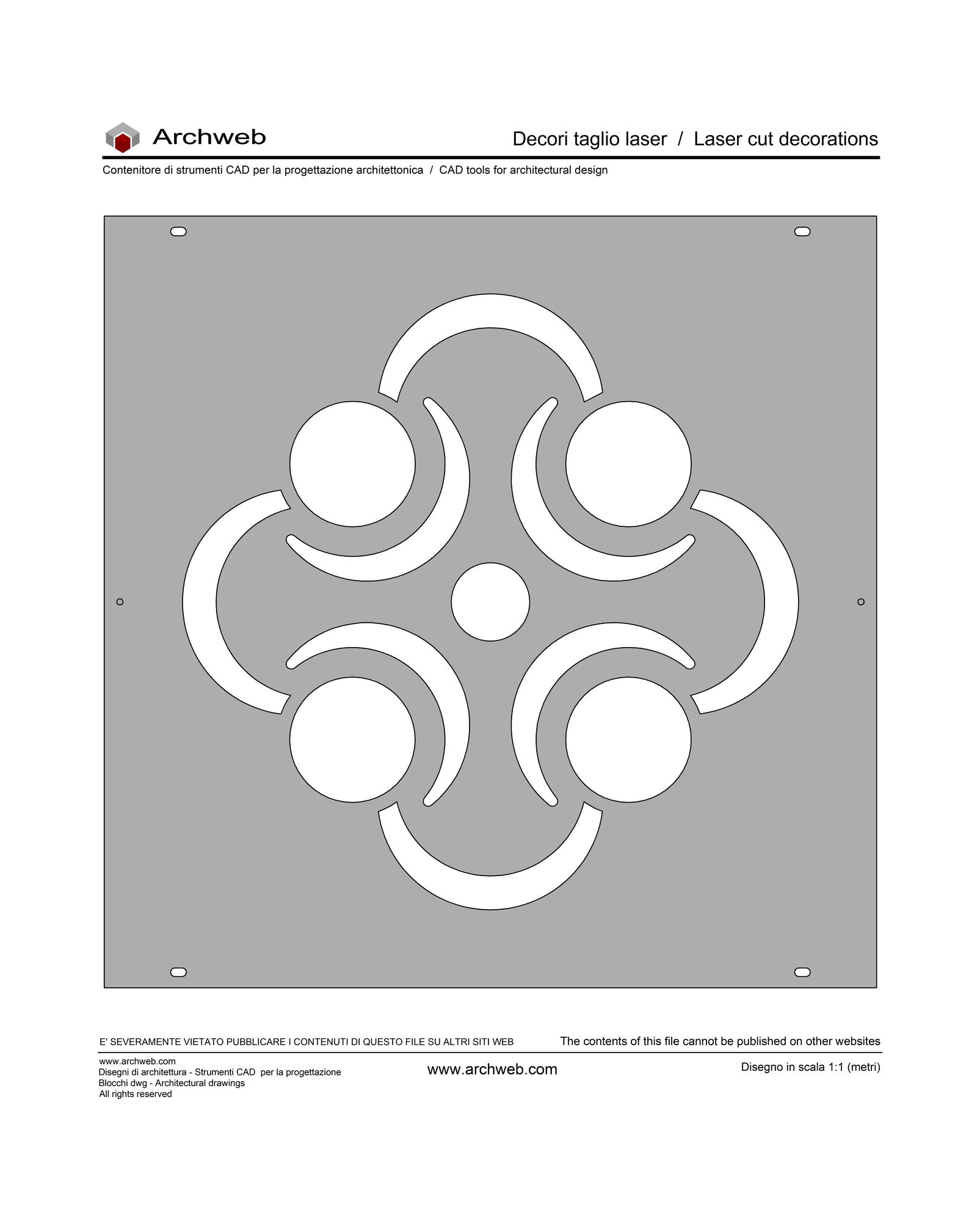

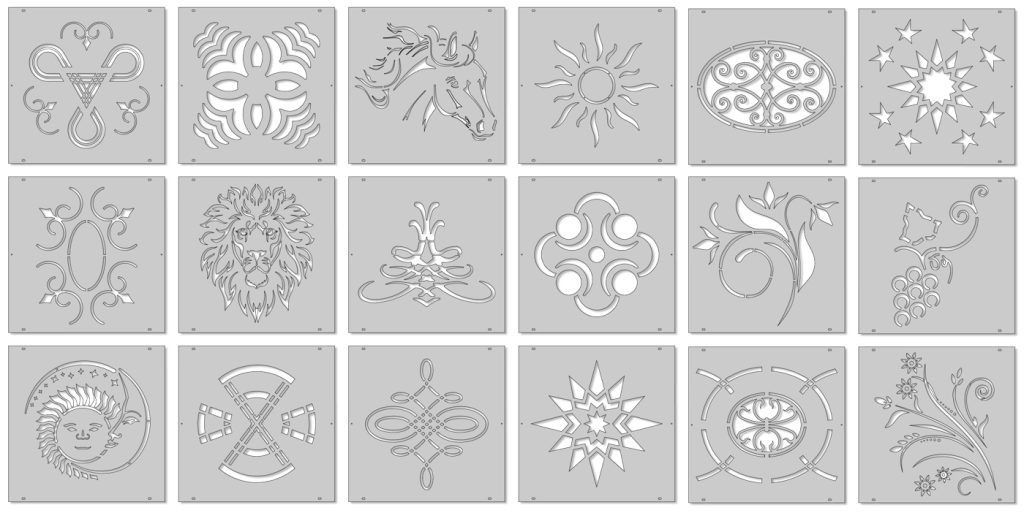

Laser cutting in metal sheets is particularly appreciated because decorative panels for fences and gates are obtained that can be customized with any design, from the geometric and simple one, to the more flexible and articulated one, which often determines a great scenographic effect. The sheets, minimum 2 mm thick, allow to have interesting effects and to be painted in the oven with epoxy powders, after hot galvanizing. COR-TEN effect painting is very fashionable.

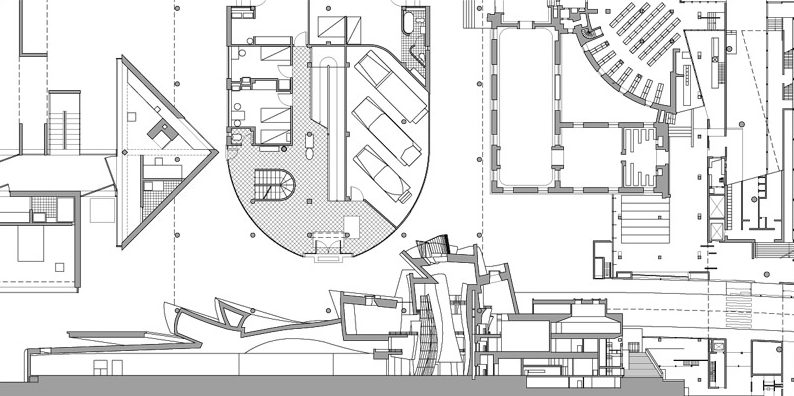

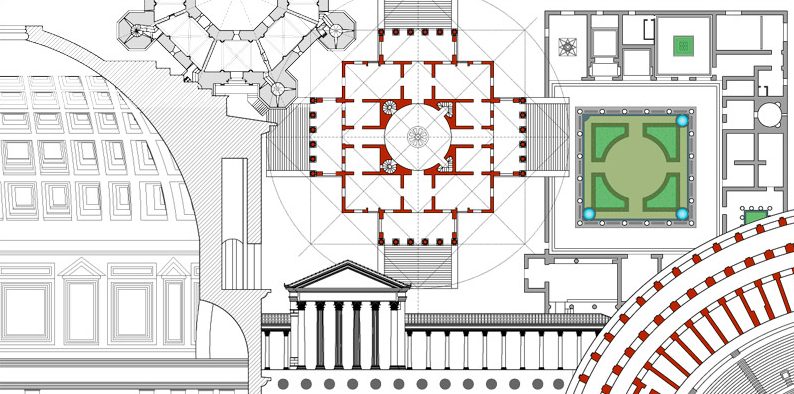

There are CAD application programs that allow you to manage the cutting paths, the geometries to be made and the checks to be carried out to obtain a high degree of precision. These programs, connected to other applications, manage scraps, warehouse stocks and other management aspects.

There are many advantages that can be ensured from the use of panels made of sheet metal with laser-cut fretwork effects:

- material that maintains its characteristics unaltered because the surface is not subjected to high temperatures;

- it is an easily reusable material, which has a practically infinite life cycle and a guaranteed duration over time;

- no maintenance is required, especially when the surface finish is made with hot galvanizing and oven painting with epoxy powders;

- the cut of the hem is of great quality and there is no need for further retouching;

- the panels can be made with customized designs with reduced processing times;

- the finished product has a great aesthetic quality;

- laser cutting ensures precision, repeatability and economy;

- versatility of use of materials: wood, MDF, iron, plexiglass, stainless steel, aluminum and corten;

- the design produced is stable over time.

For railings and gates the most suitable materials are iron and steel, aluminum is also used. Iron has characteristics of resistance, malleability and strength, steel resists oxidation and the effects of the surrounding environment and is particularly suitable in conditions of salinity, humidity and the presence of other chemical agents. The railings and gates can be made with floral, wavy, latticework and geometric Greek designs, with naturalistic elements and openwork or with abstract shapes. In short, there is really the possibility of obtaining decorative panels with any type of design that, designed in vector form by computer, can be sent to factories that are located at a distance and made with any shape and shape.

The cost of laser cutting is getting lower and lower and depends not only on the type of material used, but also on the use of the machine, the linear meter calculation of the design to be created and the type of finishing. Some models with standardized designs and sizes are offered at very advantageous prices and comparable to other types of railings and fences.

The personification of the railings also allows the possibility, in addition to the realization of various shapes and inlays, to insert symbols and logos, moreover you can choose the size and characteristics of the tunnel, from those that leave larger openings to those that have limited openings and guarantee greater privacy.