Dry construction systems

The most used materials as dry systems

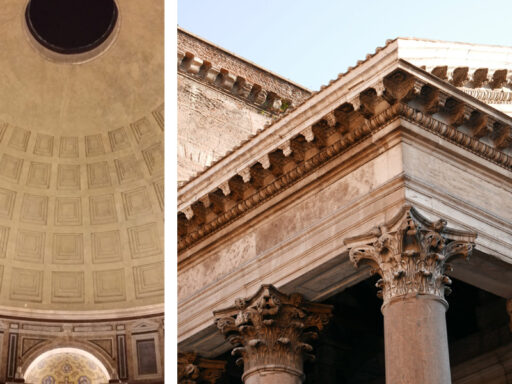

We are used to thinking of buildings as made with the aid of reinforced concrete, bricks or stone, with the use of hydraulic binders that require drying times. A motto recalls the process of drying the walls “those who wall in winter, walls forever“, to remember that it is necessary to build walls that take a long time to dry the mortar used and, to obtain the certificate of skill for the real estate units, it is necessary to expressly declare “that the walls of the building have dried up and the environments are healthy”.

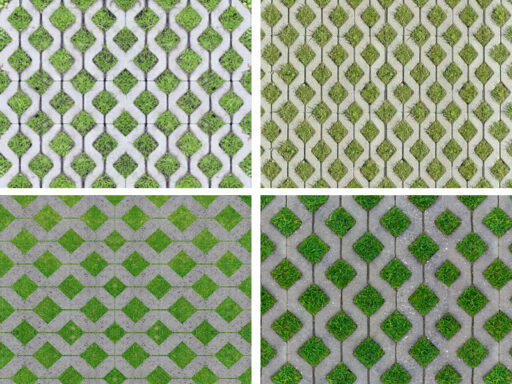

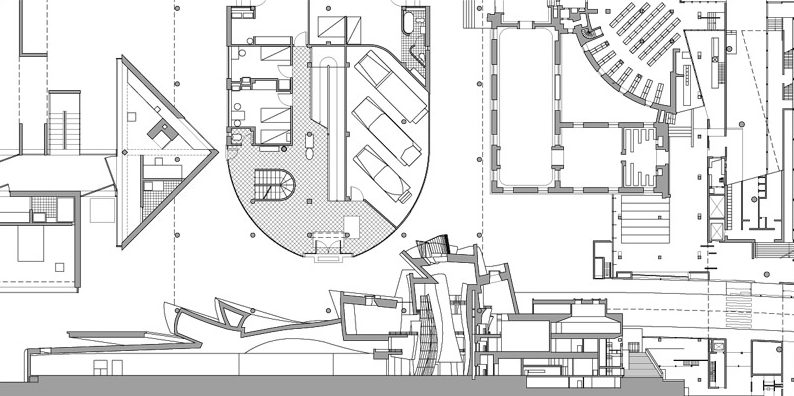

We are therefore not used to thinking of constructions as construction systems that are made with mechanical joints, screws or joints. We are more easily willing to think of systems of this nature if we think of industrial buildings or something that is temporary, made to be dismantled and reassembled. Instead, it is precisely on this principle, which allows disassembly and, therefore, easier recycling of materials, that the spread of dry construction is based, which can be compared to green building.

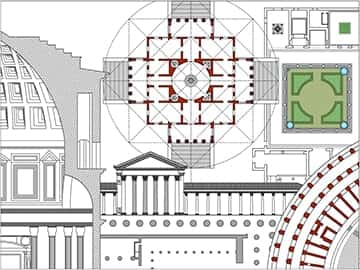

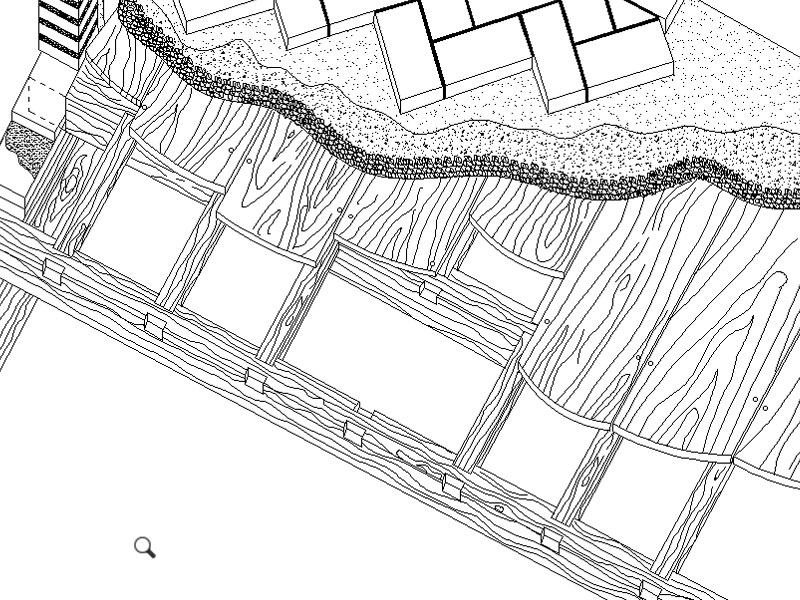

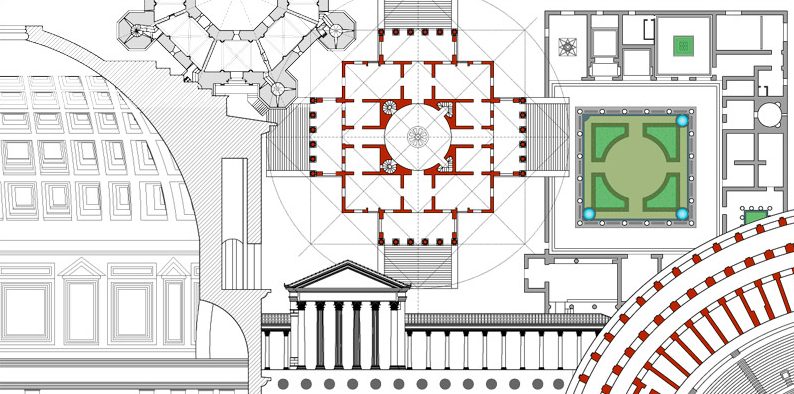

The materials most used as dry systems are steel structures and wood structures, both of which have a long history. In the field of metal materials, first cast iron was used, already used at the end of the 18th century to build bridges, up to the consecration of steel as a building element, with the Eiffel Tower, built for the international exhibition in Paris of 1889, destined to be disassembled, and, instead, still there to demonstrate the great ductility, versatility and durability of the material.

Wood, on the other hand, is an even older material, one of the first used by prehistoric man who, when he freed himself from the caves, used it to build stilt houses, terramare, the first huts for shelter. Wood has also been used for very tall buildings, as in the case of the Japanese pagodas, which are buildings with a multi-storey tower shape, strictly built in wood. There are centuries-old pagodas, demonstrating that it is a material that, under certain conditions, has a remarkable durability and enormous resistance to seismic agents.

Dry construction, some advantages:

- versatility of construction materials;

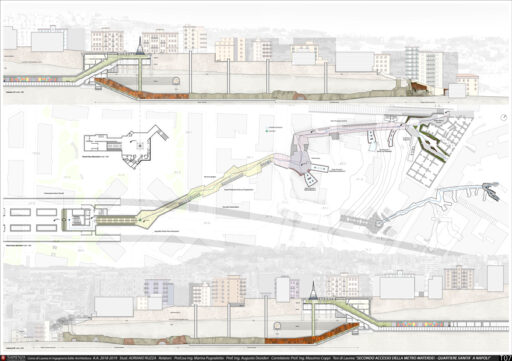

- possibility of manufacturing structures in the factory and assembling them on site with reduced production times and greater control of the result to be obtained;

- quick construction of the structure;

- the reduced execution times reduce the risks for safety on site and the related costs;

- use of prefabricated elements subject to safety regulations and preventive controls that guarantee their quality;

- more sustainable system from an environmental point of view, because the materials are recyclable and reduce the waste of raw materials;

- less production of waste materials compared to the construction phase with the traditional wet system;

- better energy efficiency of the building;

- the built structures are lighter, weigh less on the foundations and, in the case of renovations, on the pre-existing structure.

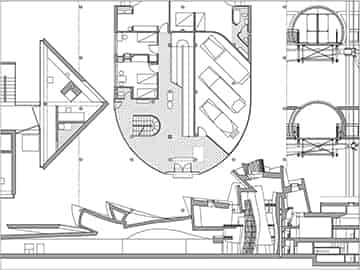

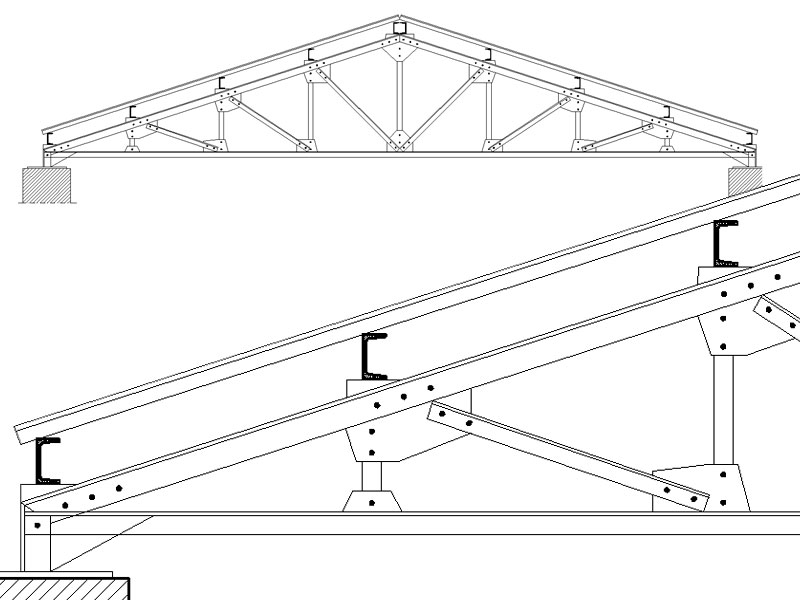

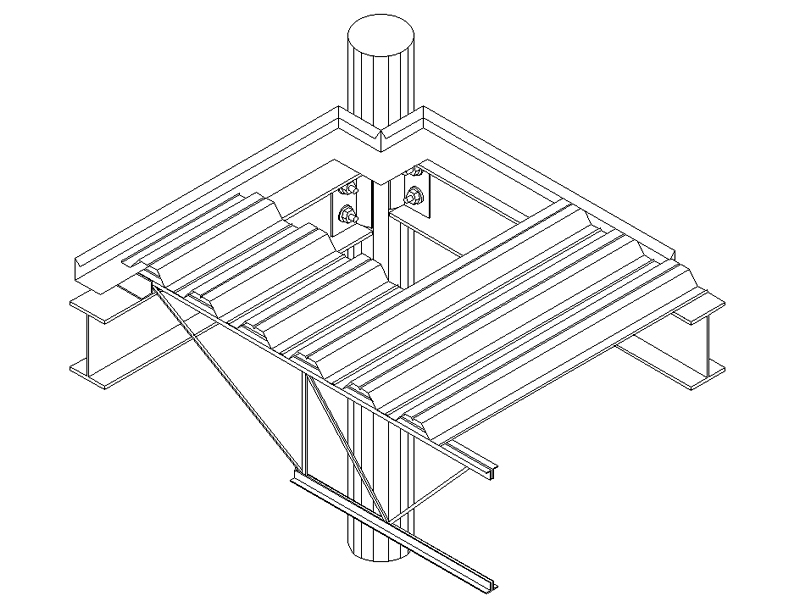

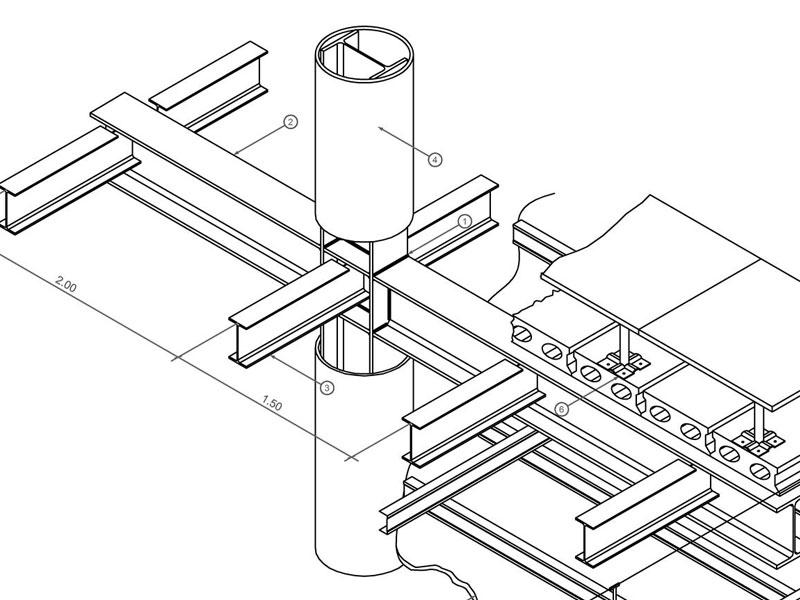

Steel structures

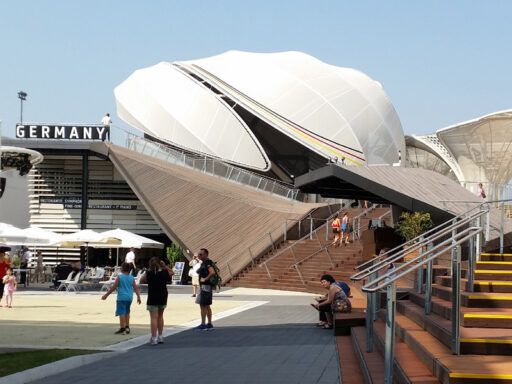

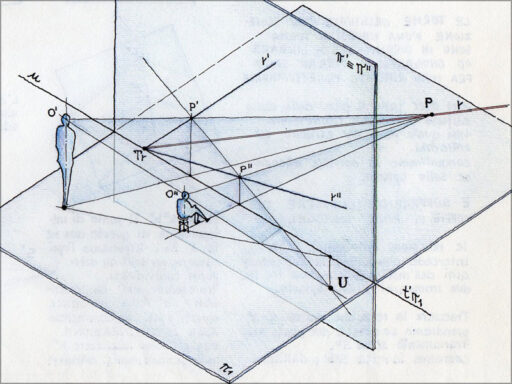

Steel makes it possible to create load-bearing structures with frame systems with beams and profiles that make it possible to create a very resistant and light structure, to be assembled in set and short times, also creating spaces with enormous dimensions. This is demonstrated by the first steel buildings, bridges, greenhouses and warehouses built in the nineteenth century, today by the large buildings and skyscrapers that are particularly widespread, especially abroad.

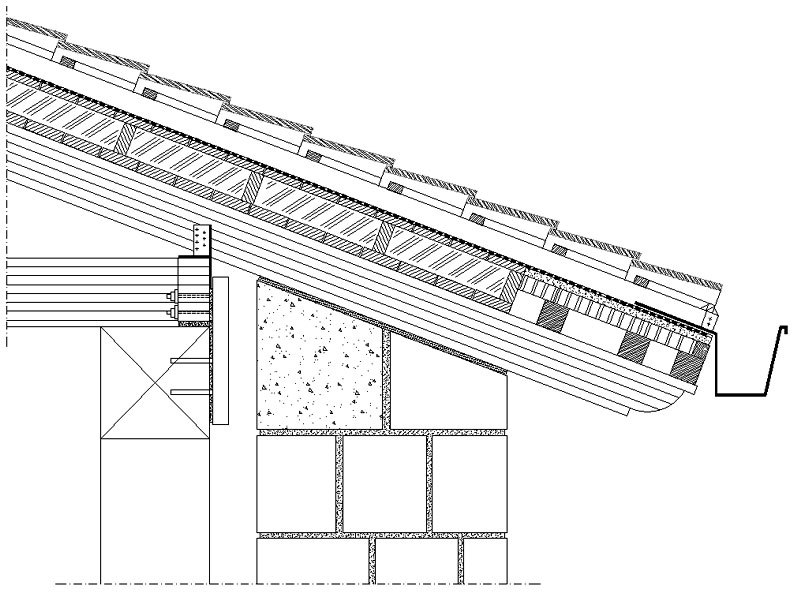

From these examples we can also move on to the construction of simpler buildings, to the construction of buildings of modest height, because the technique does not change. The structure is built with pre-packaged systems to be assembled on site and it involves completing the external envelope with dry systems, generally stratified elements with the insertion of panels to perform the task of thermal insulation of the building.

To create the internal distributions, steel frames are used on which plasterboard walls are usually mounted.

The roof of the building is made with layered panels, also with techniques that allow the creation of ventilated and suitably waterproofed cavities.

Some of the advantages of using steel:

- it allows you to significantly reduce construction times;

- wide flexibility and versatility, with the possibility to customize the final product;

- enormous resistance to seismic events, also thanks to the presence of joints;

- combination possibilities also with other construction systems;

- lightweight material, which places little weight on the foundation;

- resistance over time; thanks to the galvanizing of the profiles, the elements are resistant to corrosion and naturally resistant to attacks by biological organisms.

Points of weakness:

- higher costs than traditional techniques, only if evaluated without thinking about the possibility of breaking them down thanks to the durability of the material.

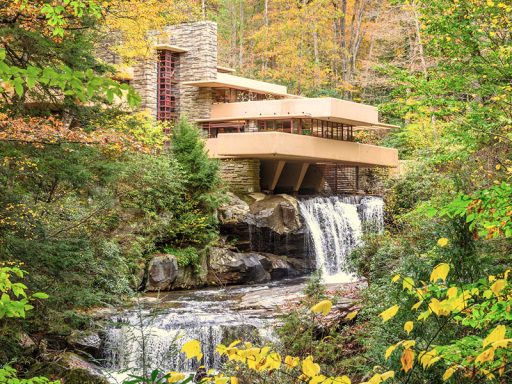

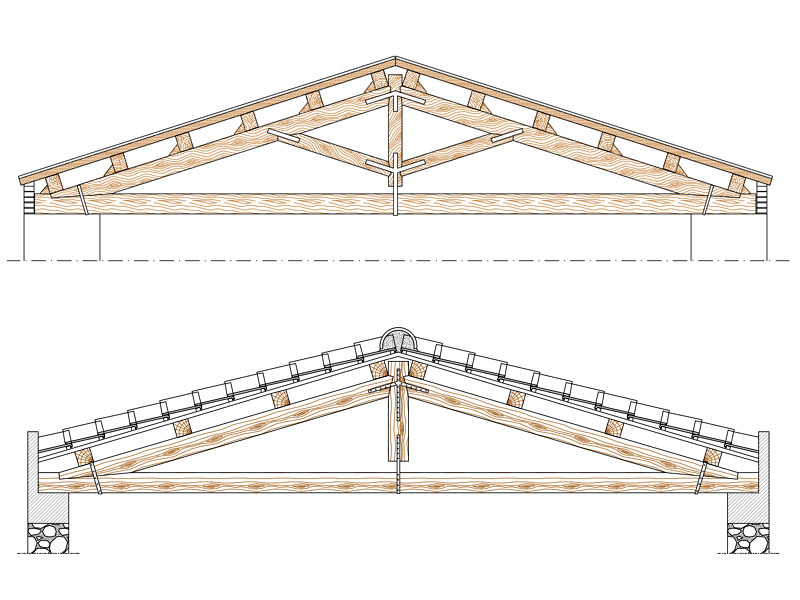

Wooden structures

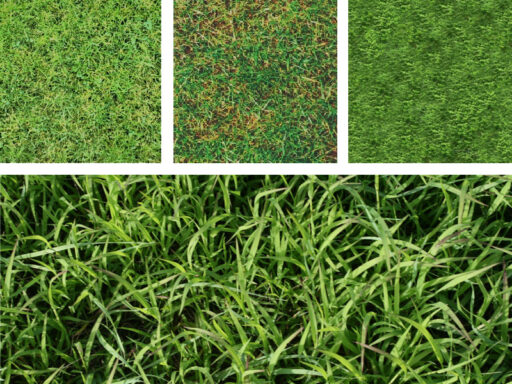

The wooden structures respond more than others to create biocompatible buildings for which the fundamental phase is that which concerns the parts of the attachment to the ground where the construction of an adequate platform avoids the rising of humidity from the ground, the real enemy of the wooden structure.

The frame of the building with pillars and wooden beams is completed with external infill, made to withstand atmospheric agents. Inside, the partitions are made with plasterboard panels. Mechanical fixings are made to make the joints between the elements.

X.Lam panels, made of solid wood in crossed layers, used both as load-bearing walls and as floors, can allow the construction of buildings with greater distances and heights.

Dry systems are also particularly effective when renovating apartments and offices. To create internal partitions, plasterboard is a very fast system, which carries little weight to the structure, it can be used to create walls, false ceilings, to create cavities in which to house ducts or to create thermal insulation systems for the building.

The plasterboard panels are fixed on steel uprights with self-tapping screws that allow rapid assembly and disassembly, with undeniable advantages in saving on construction times.

Some of the advantages of using wood:

- it is a light material that can be transported and handled easily;

- the assembly is fast, carried out dry through connections with steel plates, screws, nails, bolts;

- it is a renewable and recyclable material, with low energy consumption in the production and installation phase;

- it has excellent performance in terms of energy saving and sound insulation, as well as in terms of breathability;

- it is an elastic material that has exceptional performance in terms of seismic resistance.

Points of weakness:

- durability must be checked, which also derives from the quality of the materials used and the treatments to which it has been subjected;

- fire behavior must be checked.