Laminate floors

Practical and economical solution

Laminate is a material introduced in the 1990s, which has undergone profound transformations over time and is now one of the most widely used in the construction sector. Although it is also used for the finishing of furniture, material laminate, and architectural elements, laminates for floors are the most marketed. This is because this solution has numerous advantages when used for the finishing of commercial buildings, professional offices and residences. First of all, its economic convenience, followed by simple maintenance and moderate resistance.

But now let’s analyze the characteristics of laminate floors better in this short guide.

The stratigraphy of the laminate dashboard

During a renovation, each choice must be measured on the specific needs, aesthetic taste and budget available. If you want to obtain a finish with a warm and welcoming look but at a reduced cost, the laminate will be optimal. Furthermore, although similar to traditional parquet, this type of flooring is more resistant to the action of the sun and easier to maintain.

Production

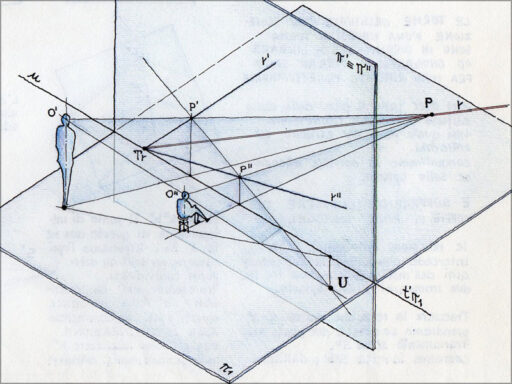

The material is used in the form of panels whose stratigraphy is standardized: only the decorative layer can be chosen according to the aesthetic result to be obtained.

Starting from the innermost layer, we find a base made up of wood particles from industrial waste and for this, the laminate is considered very sustainable. These fibers are made to adhere through pressure with special non-toxic and safe resins for human health.

The decorative layer follows, consisting of a textured sheet that emulates the appearance of a particular wood essence. The latter is covered by a plastic film, the overlay, which increases the resistance of the panel and protects it.

Through a particular procedure, synchronization, this protective film will adhere better to the decorative layer and will return a better aesthetic result that will be characterized by the chiaroscuro, typical of real wood. Sometimes, the panel can be equipped with an underlying mat that attenuates the noise and improves the adhesion of the laminate to the existing floor. However, this solution is recommended only in the case of temporary floors or floors with low humidity, as in other situations it is advisable to install an independent underlay that acts as a vapor barrier.

HPL or CPL laminates

It can therefore be said that the material appears as a layered panel that undergoes a die-casting through which, thanks to special thermosetting resins, the surfaces of diversified material take root among themselves. The process by which the laminate is produced in the factory can be of several types and determines the characteristics of the panel. Strong pressure at elevated temperatures produces HPL laminates, lower but continuous pressure generates CPL laminates.

From a production point of view, if once the material was introduced as a low-cost and easy to manufacture product, today innovative technologies are able to provide cutting-edge solutions and quality laminates. Precisely for this reason, it is necessary to clarify immediately the intended use of the rooms that will host the flooring. If the cheaper products are suitable for warehouses, fairs and temporary spaces, for residences and environments of greater value, it will be necessary to opt for a more performing and aesthetically pleasing choice.

Characteristics of laminate and differences with traditional parquet

As already mentioned, the laminate module is characterized by a rigid layering. The technique with which it is produced determines its resistance. This characteristic is shown on the panel by the abbreviation AC, followed by an increasing number and directly proportional to its value. Higher values correspond to better performance and increasing quality.

Depending on the intended use and specific needs, it will be possible to choose panels in:

- medium-low performance polystyrene;

- polyethylene that can be coupled with other materials such as aluminum to improve its resistance to heat and fire or cork to opt for a more sustainable choice.

The thicknesses

It is then necessary to consider how, against a higher initial cost, a thicker and more structured flooring increases the quality standards in terms of acoustic insulation and resistance. The thickness varies from 6 to 12 mm; in the presence of pets, an 8mm solution is usually recommended, while the value must increase in the case of floors constantly subjected to foot traffic, such as those in public buildings.

One of the most popular aspects of laminated parquet concerns its installation, which is easier to manage and shorter times. In fact, the planks are laid without the need for adhesives, fitting the elements together. It is essential that a suitable mattress has been inserted first to block humidity and reduce footfall noises. The floating installation, in addition to ensuring shorter times, allows you to assemble and disassemble the floor easily and several times.

The finishes

To achieve a correct installation of the floor, it will be good to provide for the purchase of laminate slabs and some elements necessary to complete the finishes. First of all, the skirting board, placed in the space created between the floor and the wall. This can be chosen in various heights and usually the same color as the laminate.

Other indispensable elements are the connection profiles that connect one room and the other within the building subject to intervention. Depending on the spatial conformation and the characteristics of the various floors, these elements can be flat or slide. In the first case, they are used in the presence of finishes of different environments but with the same height, while in the second, they are necessary if there is a difference in level of flooring between one room and another. There are also elements designed as a termination for the floor, affixed when the skirting board is not provided, to fill the gap between the laminate and the wall. Finally, in the presence of a staircase, step profiles will be required, which are inserted in the space between the riser and the tread.

Another aspect that distinguishes laminate from pure wood concerns its greater ability not to alter its color compared to sunlight. This material is also more resistant to wear, in fact it is more recommended than wood in environments where there are chairs with wheels such as offices and professional studios, since it is less delicate to scratches and incisions. Finally, maintenance over the years is also less demanding: the laminates do not require special and expensive treatments and are better resistant to accidental water spills.

The most common types of laminate

Compared to the times when laminate was introduced in the construction market, today this material can be found in various types that differ from a chromatic, qualitative and sustainable point of view. For this reason, even if it was born as a product widely used in do-it-yourself, it is good to make careful choices and if possible, rely on the advice of qualified technicians.

As announced, the first distinction concerns the production method: HPL laminates, very high pressure products and CPL laminates, products at low and continuous pressure. Another aspect that differentiates one laminate from another is related to the materials that make up the internal layer. In fact, we can find laminates on the market with melamine sheets, laminated with PVC or with recycled plastics, designed to be non-toxic and safe for human health. Finally, one of the most innovative products, used especially for kitchen tops, thanks to its high heat resistance, is fenix.

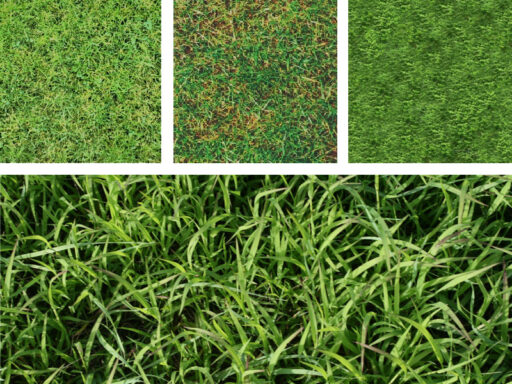

From an aesthetic point of view, the laminates can produce different effects, through the printing of the decorative sheet. They range from those with a wood effect, with chiaroscuro and real veins typical of the natural material, to those that reproduce marble materials. Furthermore, the finishes can make the various laminates opaque, shiny, brushed and porous.

Pros and cons of choosing laminates

Like any compositional choice, the one relating to laminates has many advantages but also some negative aspects that it is good to know before proceeding definitively and finding some unpleasant surprises.

So let’s see what are the main pros and cons related to this material.

PRO

- Flexibility: the laminate can be used in environments with the most different intended use.

- Low cost: the cost of the material and installation is lower than that of a traditional wooden parquet.

- High resistance: withstands bumps and scratches, which is why it is very suitable for functional environments.

- Durability over time: it does not change its quality and color with respect to the action of sunlight.

- Simplified installation: sometimes you can do the do-it-yourself but it is advisable to entrust the installation to a technician who will carry out the work in less time and at lower costs than with another type of finish. Furthermore, it can be laid on an existing floor, without requiring masonry work.

- Easy maintenance: it is easy to clean and does not require specific treatments like natural wood. To preserve its integrity, it is sufficient to avoid stagnation of water and corrosive materials.

- Sustainability: it is made up in part of recycled materials and if it is of quality, its production process respects the environment, thanks to a low impact in terms of harmful emissions.

AGAINST

- Aesthetics more plastic than natural compared to the wooden plank.

- Poorly insulating from the acoustic point of view if the thickness is reduced and if a suitable mat is not affixed.

- Low impermeability in the cheaper types.

- Not very breathable if highly waterproof.

In conclusion, laminate floors are an excellent solution for those who want to obtain an elegant and warm-looking finish like parquet but at a lower cost. In addition, they are perfect for environments in which careful maintenance cannot be carried out. The material is therefore able to ensure a good value for money and if chosen with care it can also return a very pleasant aesthetic.