The largest umbrella cover

Made of laminated wood

The largest built in Europe: 8000 square meters of innovation.

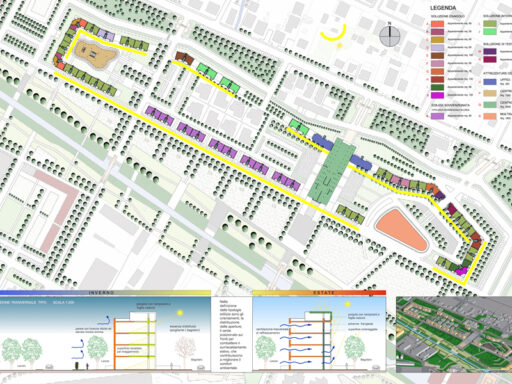

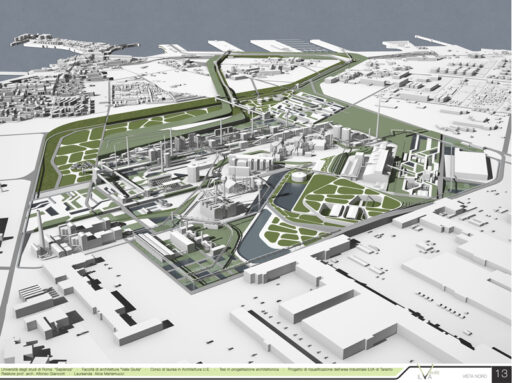

The large area of the former Cortenuova steel plant, despite being tangent to the Milan-Venice railway line and connected to it by a now disused airport, occupies a secluded position with respect to the major road communication routes (SS. 11, SS 498, SS573, A4) in the center of a vast area of the Bergamo plain still completely agricultural today.

The strong purpose of the current Municipal Administration and the conviction that the decentralization of the area from the surrounding urbanized and congested areas constitutes a privilege in the accessibility and livability of the site transformed from a disused area to a place of work and meeting have determined the recovery of the former steel mill.

It was therefore decided with determination, courage and hope that this area would constitute at the same time a place of new activities and meeting and therefore a place of economic and social recovery for both the local community and those nearby.

The project

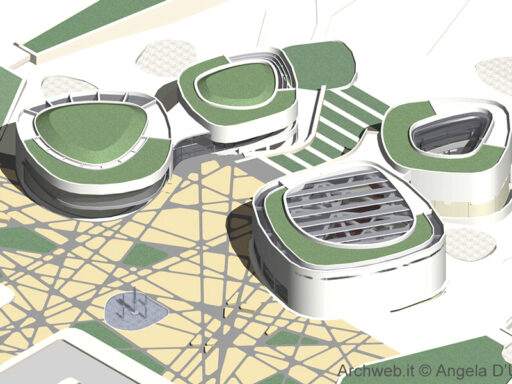

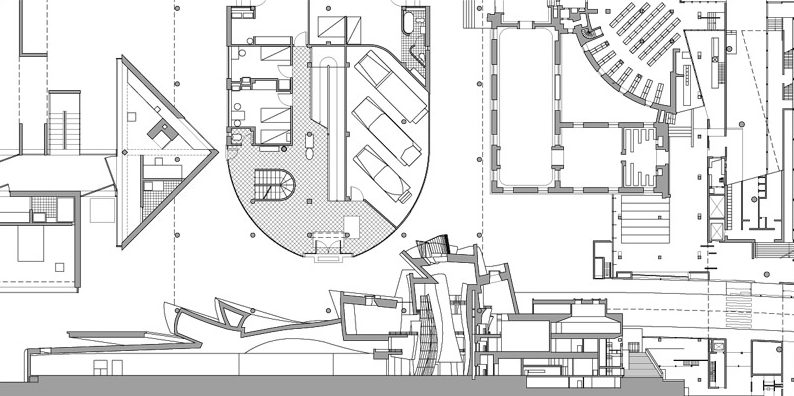

It is on this basis that the architect Gianni Roncaglia started one of the most significant achievements of the moment. Within these will of urban transformation and social enrichment, he created the new “Commercial village: Le Acciaierie” consisting essentially of four detached but interpenetrating buildings in the activities that they will host, the latter designed to assist and mutually enrich each other:

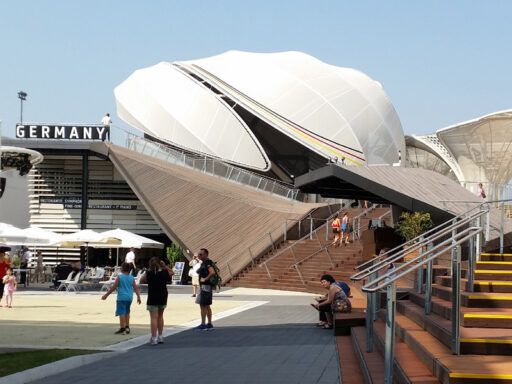

- the shopping center with its large square covered by the enormous transparent shell of the umbrella dome intended to be essentially a place for meetings, entertainment and catering;

- the “city park” which encompasses more fun and recreational activities, from multiplex cinemas to bowling and from various panoramic refreshment points to game rooms;

- the hotel with its one hundred rooms, large rooms for wired video conferences and its helipad;

- the small brico center with its specialized activity aimed at providing materials and means for small leisure time activities.

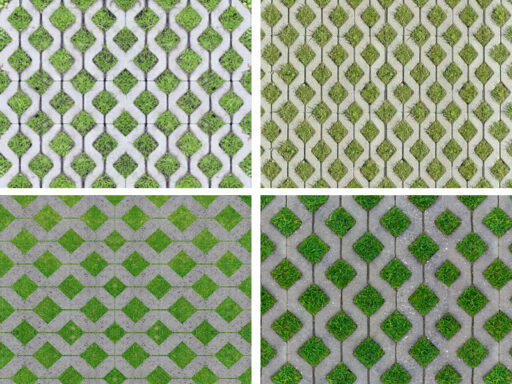

At the service of this large transformed area, major communication works have been started and are currently being completed, including the recovery and reactivation of the railway yard, works for the collection and dissipation of rainwater underground, works for the collection, treatment and the disposal of civil waste, environmental reconstruction works with intense planting and construction of green oases, construction of new energy and telephone backbones.

Realization

In order to create the futuristic shopping center, the architect Roncaglia was supported by 2 important companies: Holzbau, for the laminated wood structures and Omatec for the aluminum and glass structures.

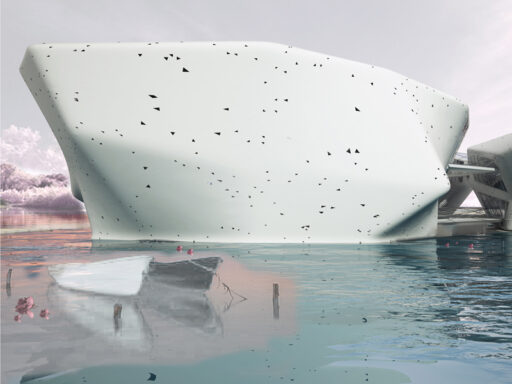

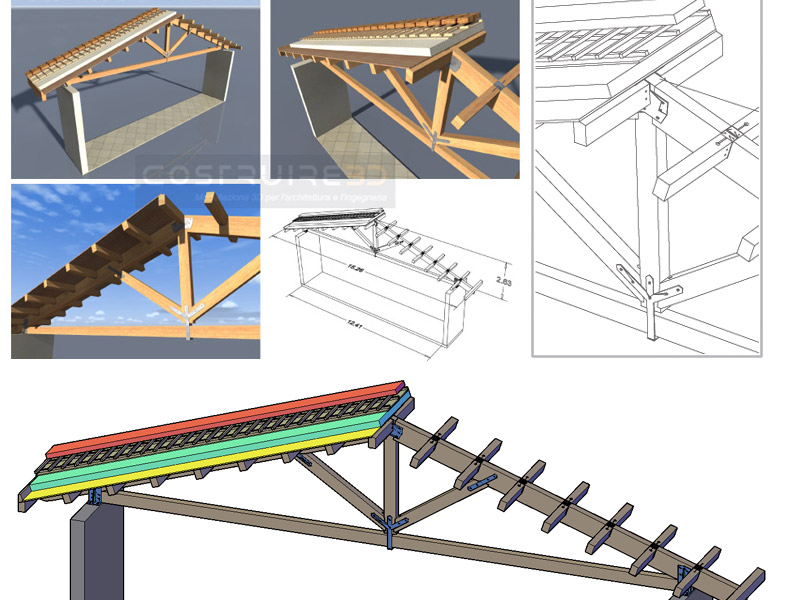

The project, which draws inspiration from the socializing form of the large circus tent, is essentially structured around a large covered space serving as a square surrounded by a set of exhibition and sales areas connected to each other by pedestrian paths.

At the center, therefore, a large common space where to place the recreational and service activities for the meeting and to occasionally host shows and entertainment events organized in collaboration between the Manager and the Municipality of Cortenuova, according to the rules and agreements established in a specific deed of agreement. All around a multitude of small, medium and large areas for the display and retail sale of a variety of food and non-food goods.

At the heart of the project idea there is therefore the precise intention of building a complex urban whole where activities and social relationships are favored by the purchase of consumer goods and by the meeting between people as well as in any neighborhood market.

Dimensions

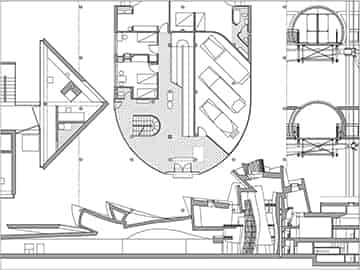

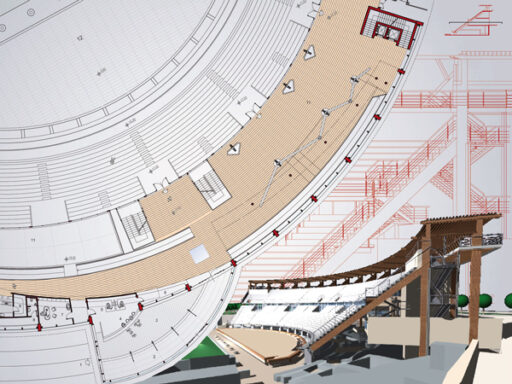

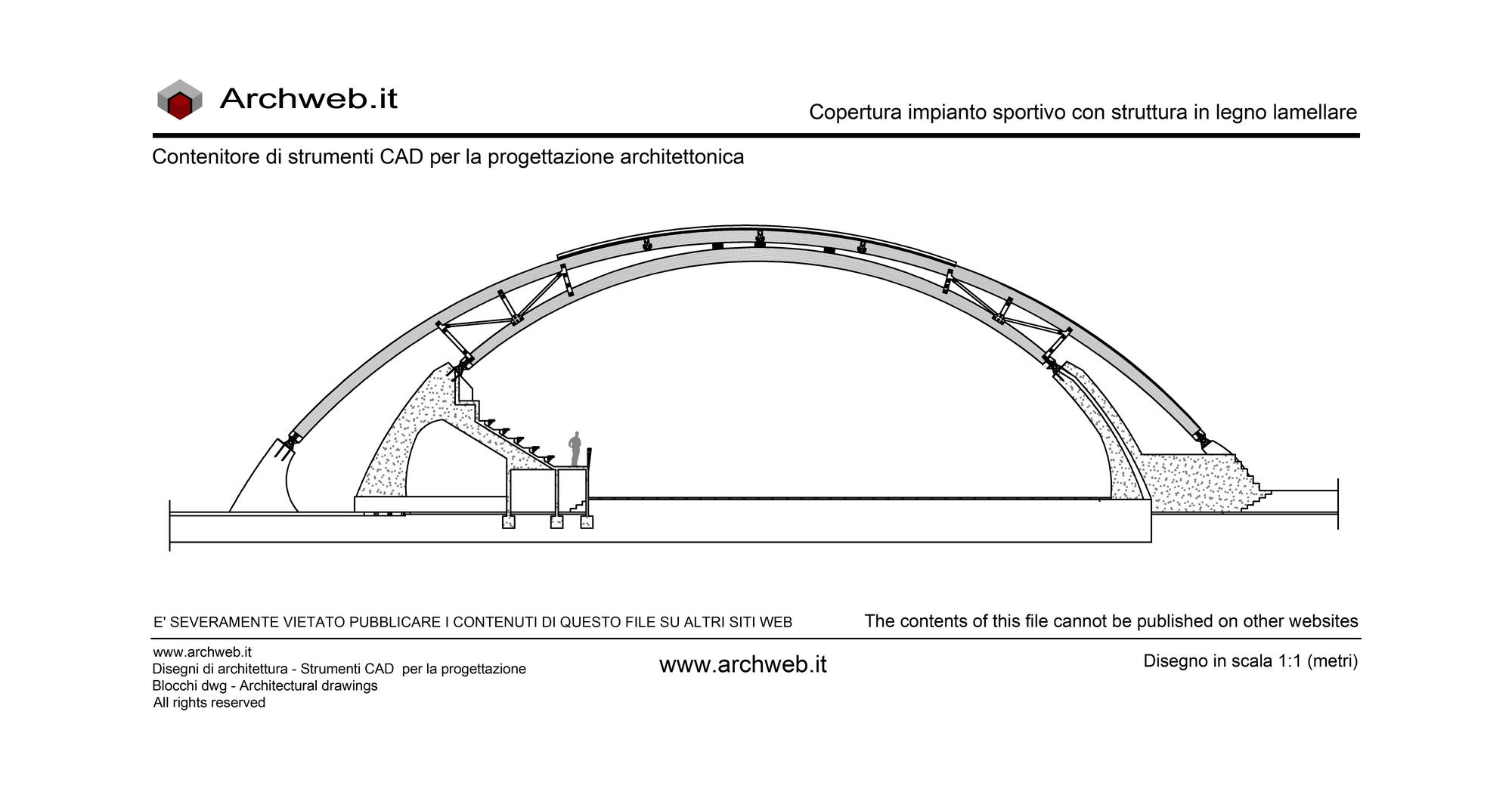

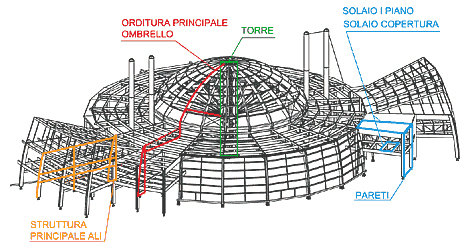

The shopping center covers an area of approximately 58,000 square meters, for the most part built in rectangular concrete, where a circular plan area stands out with a glass roof and two symmetrical side wings perimeter to the circular area. The structures of these latter parts were entirely made of laminated wood.

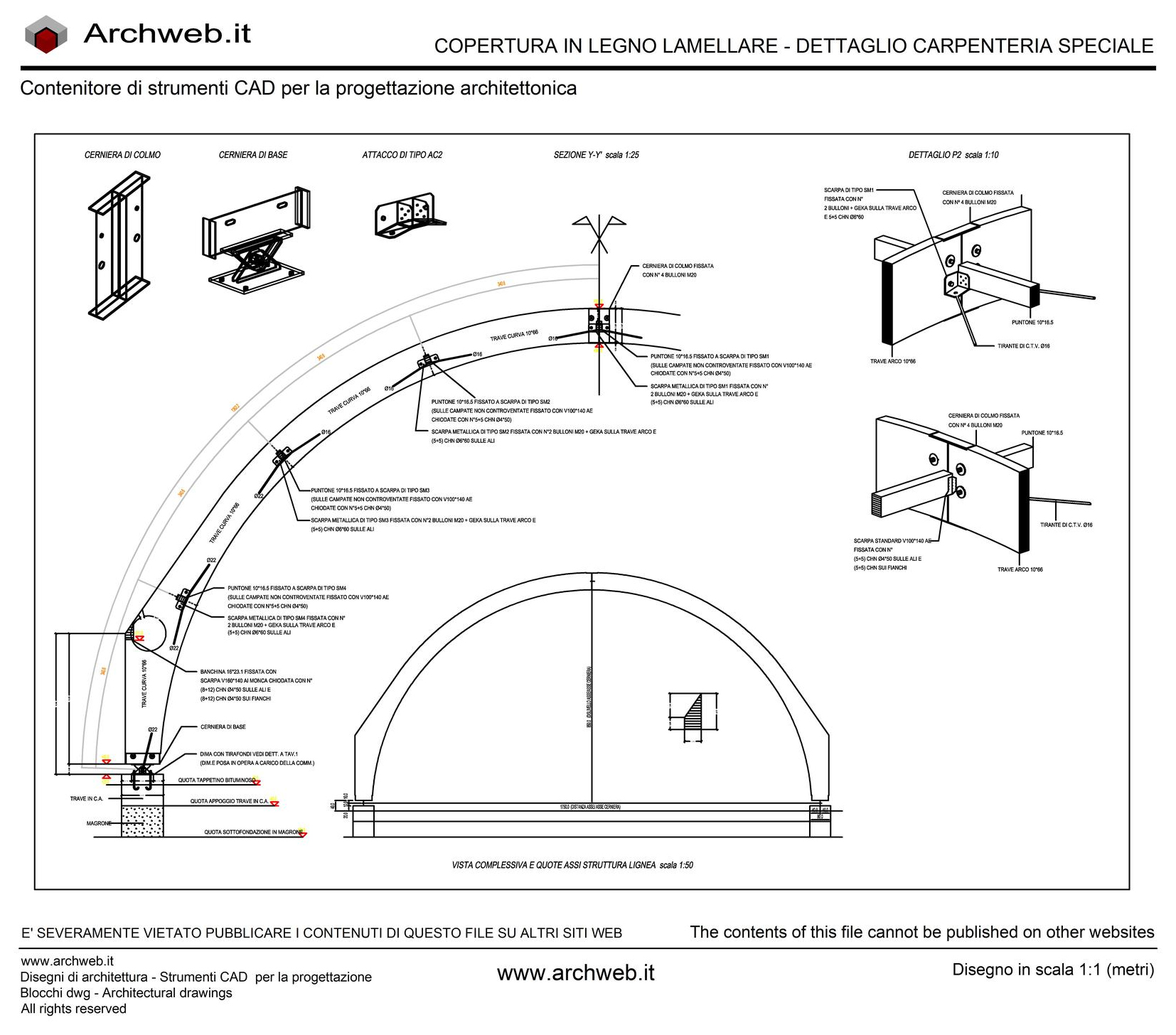

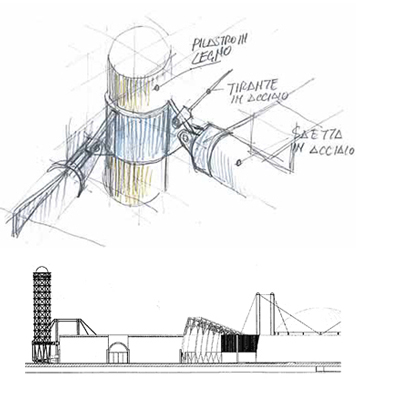

The structure of the circular area covers the square of the shopping center and consists of a laminated wood roof with a diameter of about 82 meters, which from a formal point of view can be defined as a huge “umbrella”. This “umbrella” is made up of two parts, a dome with a central tower and an almost flat circular ring along its entire perimeter.

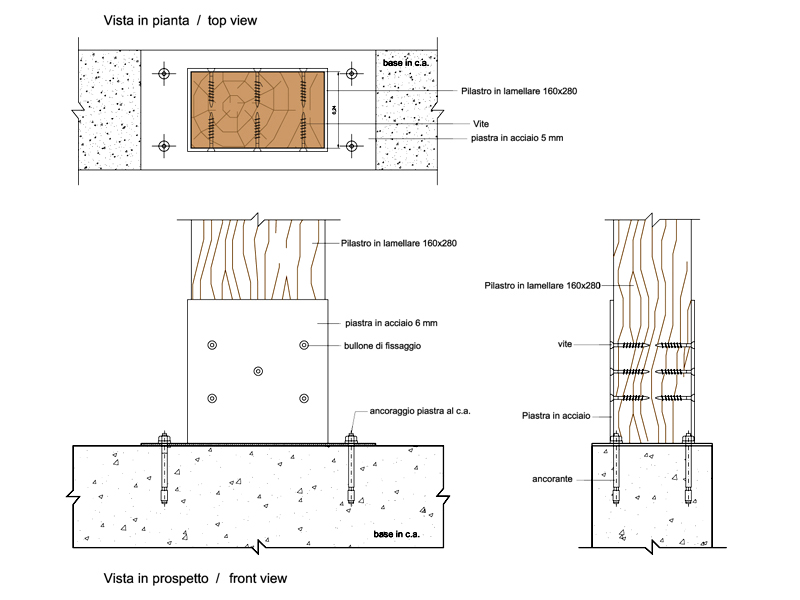

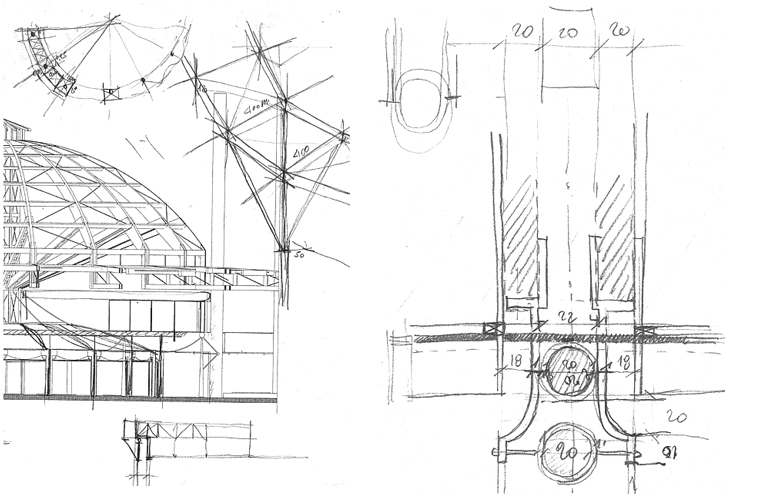

The dome with a diameter of 43 meters is made with laminated wood arches. The arches are hinged in the upper part, towards the center of the dome, on a central torrent, 29 meters high; while the other end is connected to a reticular beam about 17.50 meters long. The other end of each reticular rests on underlying reinforced concrete structures, or is connected to a system of vertical laminated wood elements that allow part of the forces acting on the structure to be discharged to the ground in the foundation.

Structure

The area affected by the reticular beams defines a circular ring roof, which completes the umbrella structure, where the extrados of the roof has a pitch slope of 5%. The height of this circular volume towards the outside is 14 meters. A glass curtain wall was created for the entire roof structure and for the entrance to the square.

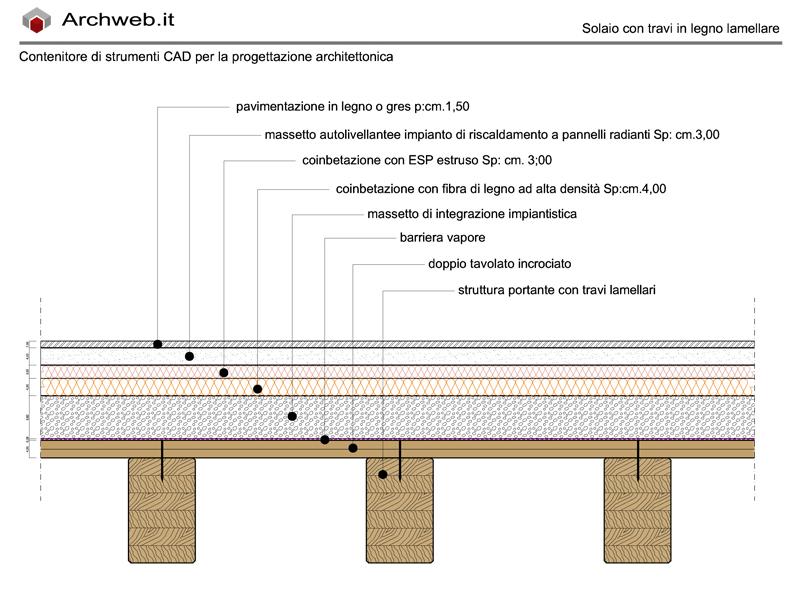

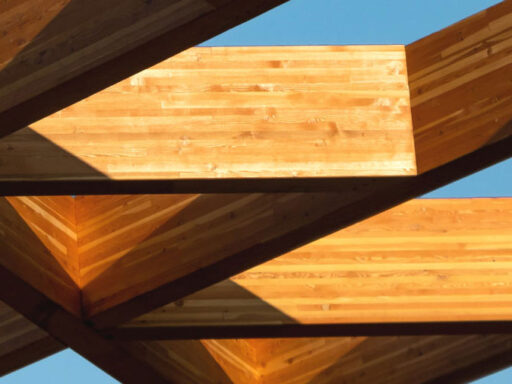

The side wings are intended to accommodate commercial and catering activities. They extend for 27.5 meters, and are made by means of a framed structure: vertical elements made up of composite columns that support reticular beams and solid beams. These beams in turn carry a system of purlins on which, at an altitude of 7.68 meters, the first floor slab in laminated wood (12 cm thick) was built. At an altitude of 13.80 meters we find then the roof slab in laminated wood (8 cm thick) insulated, above which there is a shed structure. For the vertical cladding of the wings, ventilated metal walls were installed using the “cassette” system.

The tower as the center of the large domed roof

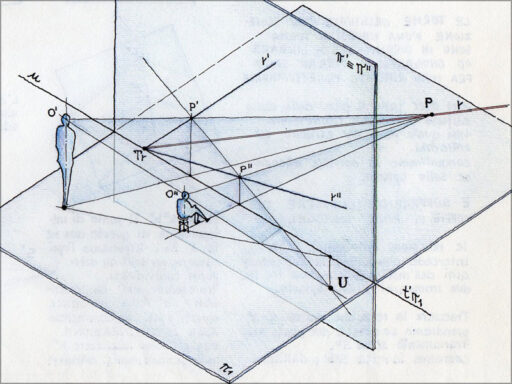

The geometry of the entire structure has as its fulcrum the center of the tower, which generates 20 rays at a constant angle of 18 °, corresponding to the arches of the dome and to the entire load-bearing system of the entire construction. In order to identify columns and intermediate beams present in the structure of the wings, further rays were introduced which therefore form an angle of 9 ° with the adjacent rays.

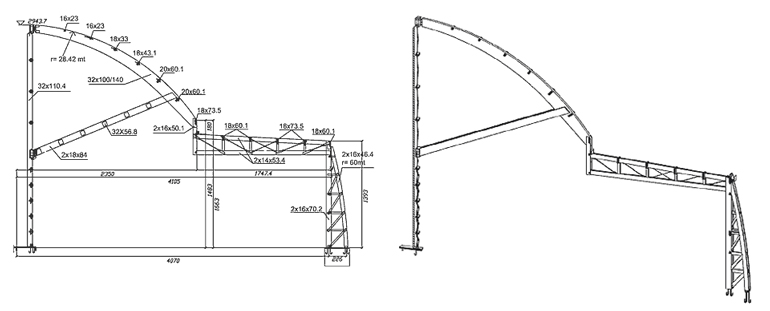

The tower with an irregular octagon base (external diameter approximately 5.10 meters) is composed of eight laminated wood columns with a section of 32×110.4 cm, for a total height of 27.87 meters.

These elements are connected to each other in two different ways. On one side with a system of laminated wood struts and steel tie rods that form a lattice on the “long” side of the octagon. On the other side, the connection consists of a series of calastrelli. This structural arrangement made it possible to optimize the rigidity of the entire tower.

At an altitude of + 12.29 meters we find a steel ring (diameter in axis 4.00 meters, height 1.02 meters, width 46.5) which acts as a support for a system of gabled struts that transmit the loads of the dome to the lower part of the tower, stressing the ring mainly compression.

On the top of the tower at an altitude of + 28.41 meters there is a steel ring (diameter in axis 4.00 meters, height 1.02 meters, width 54.2 cm). Each arch of the dome connects to this ring via a single pin hinge. In this way the ring is substantially subjected to traction and also transmits part of the vertical loads from the dome to the underlying tower.

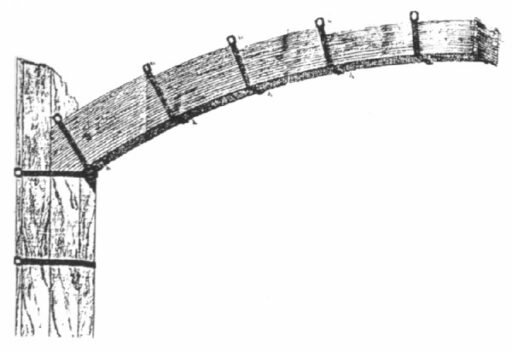

The main structure of the dome

The main structure of the dome is made up of 20 laminated wood arches with a section of 32×100 / 140 cm with a radius of curvature on the extrados of 28.42 meters, connected at the top, on the central tower by a hinge and to the lateral lattices by means of vertical elements ( section 2x16x50.1 cm) which make up a drum. The latter connects the hemispherical dome with the flat part of the circular ring.

In correspondence with the first perimeter span of purlins, each arch is connected to the tower by a calastrellato strut (section 2x18x84 cm). The presence of the calastrelli allows to increase the rigidity of the strut with respect to the lateral heel due to instability and to maintain the “lightness” of the structure.

Hence the formal analogy with “the umbrella”.

The secondary structure has rectilinear beams with variable section from 20×60.1 cm to 16×23 cm, depending on the static light, with a distance of 3.53 meters.

The main covering structure of the circular ring is made up of reticular beams (total length 17.88 meters), whose lower and upper bridles are made with double beams with a section of 2x14x53.4 cm. These beams are connected to the vertical elements of the drum by means of supports in correspondence with the upper bridle of the reticular beam.

The total height of the trusses is variable, given the 5% slope of the extrados of the roof, from 2.70 m (in correspondence with the connection with the dome), to 1.83 m towards the outside of the structure.

The secondary structure is made up of rectilinear beams, with variable section, connected to the lattices by means of retractable steel brackets.

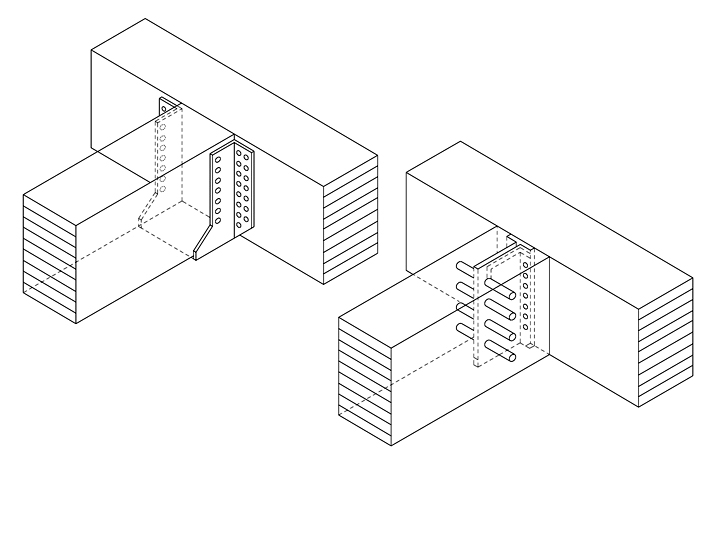

Connection joints

The joint of the reticular beams towards the outside of the structure has three types:

- support on the reticular columns in laminated wood;

- support on reinforced concrete structures;

- joint on the curved columns of the facade.

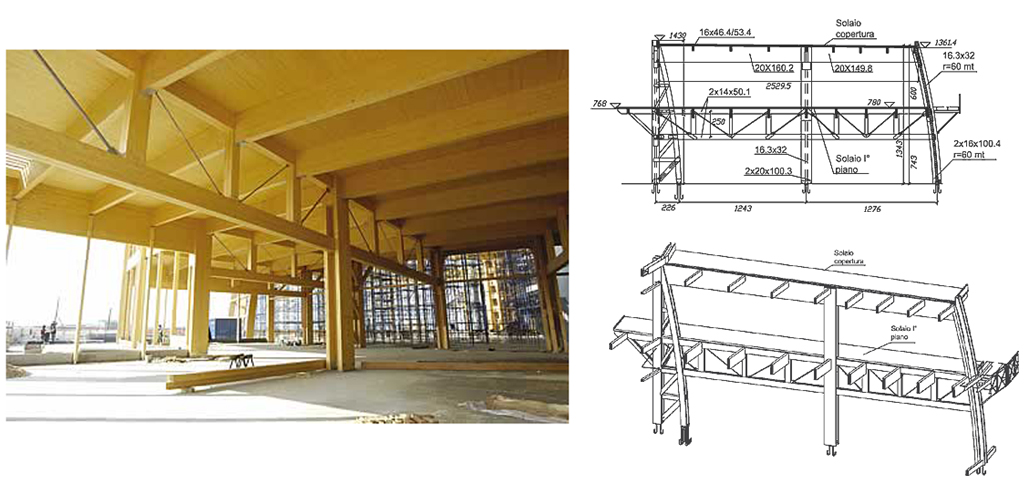

The two wings in the original project had been foreseen in concrete, but during the definition phase of the executive project the problems that emerged from the use of this material led the client to evaluate and consequently opt for the use of laminated wood.

They are made using a framed structure, with an intermediate floor, with a total span of 27.45 meters. We find three types of vertical load-bearing elements: reticular columns, intermediate straight composite pillars with “H” profile and composite pillars, always with curved “H” profile on the facade.

The load-bearing horizontal elements of the floor I °

At the +7.80 level, they are made up of reticular beams, to which purlins (secondary structures) are connected via hidden steel brackets.

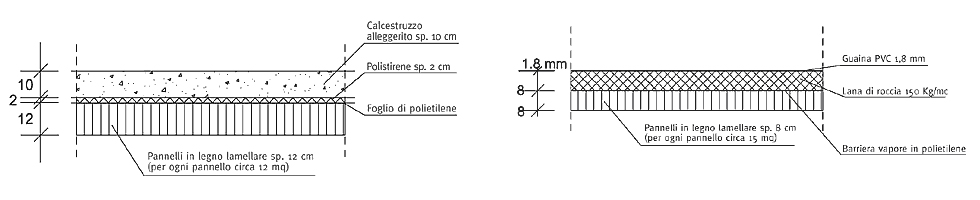

The laminated wood floor is made up of panels with a thickness of 12 cm, laid side by side and screwed to the purlins, and was then completed with 10 cm of lightened concrete with interposed polyethylene sheet. The attic at this altitude forms a balcony towards the internal square of the shopping center.

The Roof covering, at an altitude of +13.80 meters, it rests on a load-bearing structure consisting of solid beams with the extrados shaped in a sloping roof, the connection with the secondary structure is the same as the floor on the 1st floor. The floor is made up of 8 cm thick laminated wood panels. The roofing package was made with a polyethylene vapor barrier, 8 cm of rock wool 150 kg / mc and a final 18 mm PVC sheath.

The perimeter walls

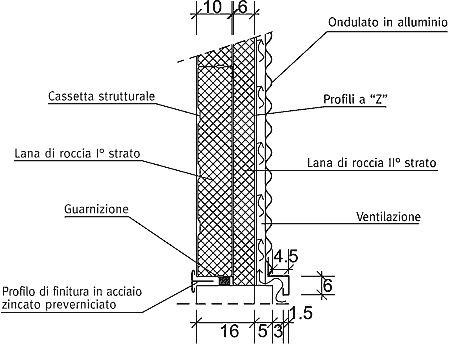

The perimeter walls are made through a ventilated “cassette” system, made with structural elements in steel (“cassettes”), two layers of rock wool, ventilation cavity and for the final mantle in corrugated sinusoidal aluminum sheet.

The two side wings are completed on the roof by shed structures. These are two interpenetrating volumes: the first has a rectangular plan and a straight extrados, inside which we find a truncated cylinder structure.

The external shed has a supporting structure made of 14×43.1 cm beams braced with steel elements, resting on square section steel uprights. The roof was made with a corrugated aluminum sheet.

The truncated cylinder structures are formed by load-bearing curved beams, laid in correspondence with the steel uprights of the upper structure, with a 10×19.6 cm section and a radius of curvature at the intrados of 4.60mt. The purlins are in arch thickness. The finishing coat was made with a corrugated sheet

Outside, the wings have been completed, at the height of the first floor slab, with a steel gallery and staircase, which serve the emergency exits.

This realization represented a real challenge for Holzbau due to the extreme particularity of the structural typology, unique of its kind, the large lights involved, the considerable complexity of static calculation and the difficulty of sizing and the complexity of the design. constructive. All with a particular focus on aspects related to the construction of such a complex structure.

The aluminum and glass casing

In this context the intervention of Omatec was inserted, the Lombard company intervened in the realization of the aluminum and glass envelope that covers the supporting structure.

This casing is made up of three distinct types characterized by different geometries, namely:

– “barrel” shaped vertical wall of 910 square meters;

– connection roof with a 4% slope of 3300 square meters;

– central “hemispherical” roof of 2300 square meters.

140 opening outwards have been inserted on the covers which, thanks to a suitable drive system, allow the dual function of EFC, i.e. smoke and heat evacuation and ventilation.

The connection between aluminum and laminated wood

The main technical problem that Omatec happily solved was the study of the interface between the different frames of the aluminum structure and the supporting structure in laminated wood.

It was a question of anchoring a complex aluminum structure characterized by dimensional variations linked to temperature differences (expansions) to a laminated wood structure characterized by its own independent movements different from those in aluminum and by certain assembly tolerances.

The aluminum structure is self-supporting from one bracket to another and unloads its own weight and any loads such as wind and snow on the substructure.

To compensate for both the installation tolerances and the various expansions and movements, a special bracket was designed using two aluminum extrusions and a stainless steel pin.

The bracket, depending on the case, performs either the functions of a trolley or a fixed point.

The bracket is able to absorb the installation tolerances of the supporting structure (+/- 15 mm) and the movements of the two structures.

The three different closures are characterized by a suitable study of the expansion and therefore of the distribution of the fixed points and of the carriages.

The careful development of the design, which in the case of the central roof required checks with three-dimensional models, made it possible to create and assemble the entire aluminum structure without carrying out any relief of the laminated wood substructure, based exclusively on the project drawings.

Technical data

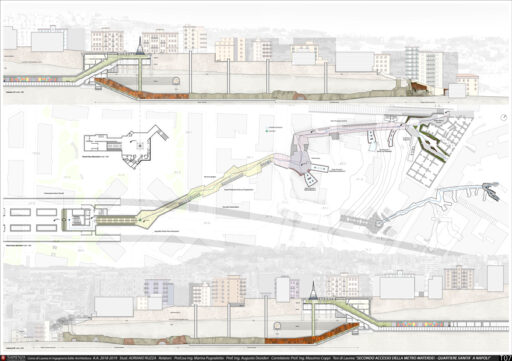

- surface of the entire area recovered sqm. 555,000.00

- new municipal road km. 3.50

- new provincial road SP 98 km. 9.00

- new sewerage system for black water km. 4.00

- new purifier for 2,000 theoretical inhabitants

- new sewerage system for white water km. 2.00

- slp shopping center. sqm. 58,000.00

- city park slp. mq. 15.500,00

- slp hotel. sqm. 3,500.00

- brico center slp. sqm. 4,000.00

- logistic activities sc. sqm. 240,000.00

Shopping center

Client: Bergamo Engineering

Construction site: November2003- luglio 2004

General designer: Arch. Gianni Roncaglia

Construction supervision: Arch. Gianni Roncaglia

Project manager: Ing. Oswald Grömminger

Static design of laminated wood structures: Ing. Oswald Grömminger e Ing. Pietro Aldi Holzbau S.p.A.

Design of aluminum and glass structures: Ing. Luigi Caneva Omatec Srl

Constructive design: Walter Tauber Holzbau S.p.A.

Installation: Oberrauch GmbH

Fire resistant: R=60′

Maximum light: 43 mt

Max height: 29 mt

Laminated wood structures: Mc 1.916

Covered area: Mq 8.000

Metallic steel carpentry: kg 166.835

related dwg drawings

DWG