Structural glass railings

A functional and aesthetic choice

The parapets in structural glass are completely made up of glass panels and do not include connecting and joining elements in other materials. These are transparent, frameless components which must be chosen and installed carefully. Once assembled, the glass parapet must guarantee safety and resistance over time and for this purpose the glass used must be solid and of high quality. These solutions can be used inside residences, commercial and service spaces, but also in outdoor environments such as terraces, balconies and garden roofs.

We will explore the following contents

- Characteristics of structural glass

- The use of structural glass

- Types of structural glass and parapet

- The legislation relating to the installation of structural glass parapets

Before proceeding to the typological choice of the structural glass parapet, it is necessary to clarify the function that is needed and the aesthetic result to be obtained. In fact, thanks to the multitude of products on the market, it will be possible to choose the type of crystals, finish, cut and additional elements that will be able to restore a very different aspect to the environments. Furthermore, at the basis of every decision, it is necessary to consult technicians and professionals in the sector able to guide the choice of products that are safe and durable over time, in compliance with current legislation and in the realization of a correct installation.

Below some advices which can be of help for those who decide to install a parapet in structural glass or for those who want to deepen the topic.

Characteristics of structural glass

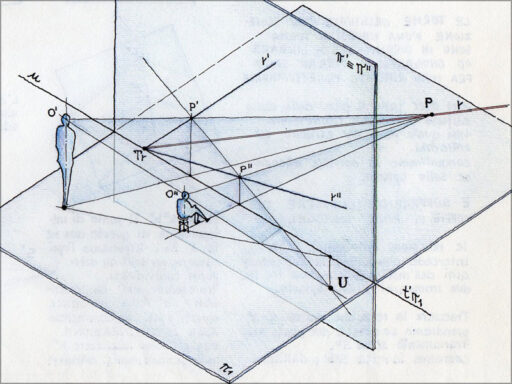

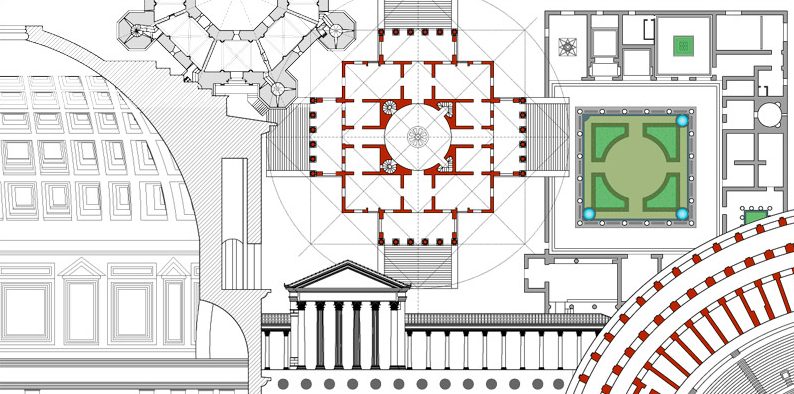

The technological evolution of glass and the introduction of innovative and high-performance products have led to the overcoming of the concept of transparent surfaces confined only to the window elements. It is from this perspective that they are studied new forms and uses of this material that sometimes comes to unexpectedly occupy entire facades, parapets and construction details. Over the centuries, thanks to its chemical-technological characteristics and its versatility of use, glass has found a growing consensus in architecture and when subjected to particular processes, it has satisfied diversified needs with unexpected results. Within this scenario, it is important to specify how this material with its numerous potential must be chosen carefully, taking into account many elements. The first aspect, typical of the crystals used in construction, concerns the resistance to stresses to which they can be subjected and the absence of weak areas. In these terms it is necessary to calculate the static loads, uniformly distributed on the surface and the permanent loads.

The strength level of the glass sheets depends on their thickness and size and the higher the strength, the more unbreakable the crystal will be. Although thicker glasses correspond to higher resistances, there are numerous processes that allow the use of thinner but equally safe glass.

In the case of structural glass, the crystal must possess specific requirements to be considered as such. The first characteristic it must be equipped with is the ability to absorb and withstand the loads and external actions acting on it.

Indeed, the high load resistancepermette to use this type of glass in load-bearing structures that would otherwise be made of materials such as wood and metal. In this way, the glass structure will house the actual panels without the aid of elements that interrupt the visual continuity. Thus the structural glass is resistant, safe and aesthetically pleasing, thanks to its essential transparency. In addition, it is very functional as it is waterproof and easy to maintain. From an ecological point of view, structural glass, and glass in general, is recyclable and promotes energy saving, thanks to its ability to filter the light and heat coming from the environment towards the interior of the building, in the case of external facades and parapets. Another very important aspect to consider is the level of structural glass safety. In fact, the panels must guarantee integrity with respect to their physical consistency, protecting themselves from accidental breakage and static safety in the event of external stresses.

Among the different types of structural glass we can mention U-glass which is obtained by pouring into special U-section bars and becomes an integral part of the structure without the need for a specific frame. Through the use of this particular type, large glass surfaces can be obtained by blocking the bars to the perimeter structure of the compartment concerned.

The use of structural glass

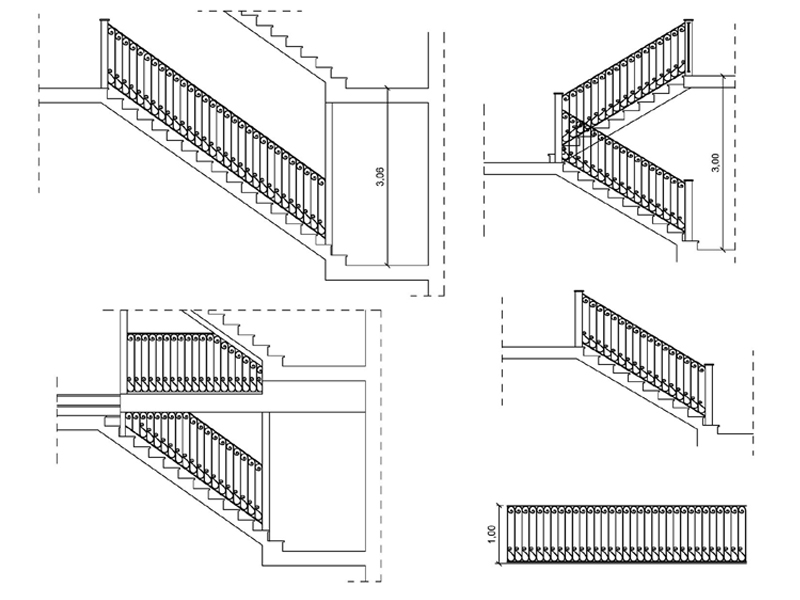

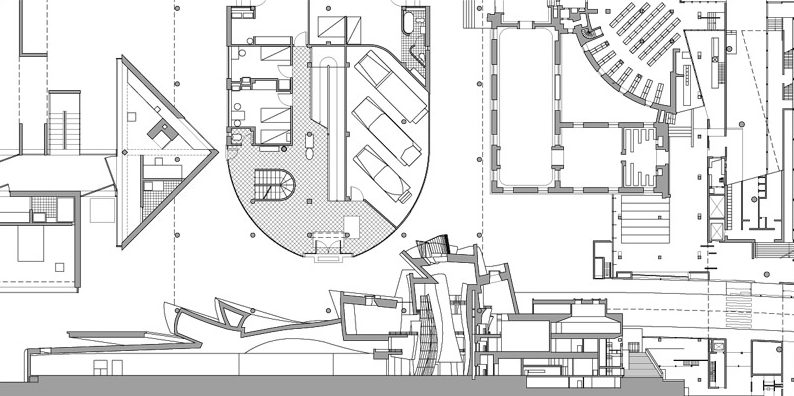

Structural glass in construction is used in numerous solutions, typical of the internal and external environments pertaining to the building. If once glass was conceived as a material that characterizes only windows and French windows, today thanks to its properties and the most innovative processes, it is used for the creation of elements with different functions. Structural glass, thanks to its load-bearing capacity, does not require framing and can cover entire transparent facades or be used for the construction of mezzanines, ramps and bridges. In addition, it often also becomes a characterizing element in the architecture or interior spaces of the house. An example of this are the parapets of private staircases inside residences and condominiums, but also those that characterize public staircases that can be found in shopping centers and buildings for services.

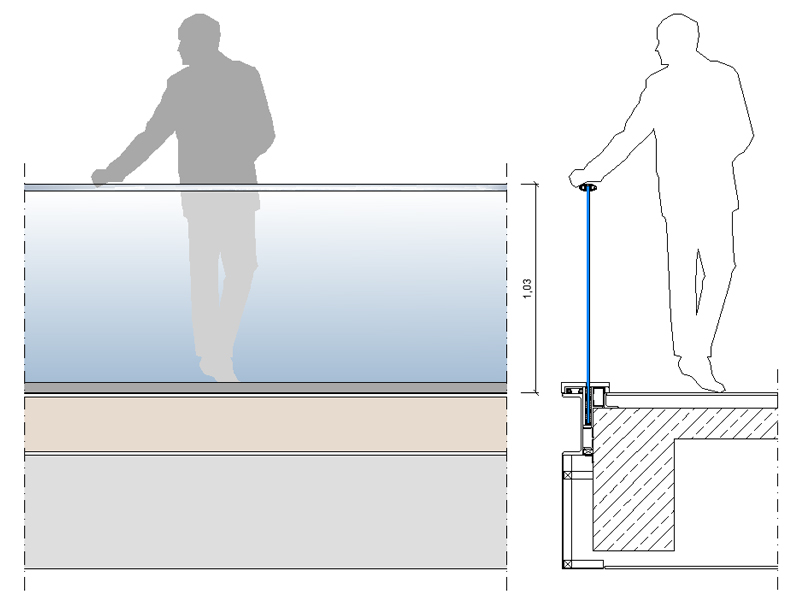

The structural glass parapets characterize balconies and terraces and thanks to their minimal elegance and the absence of interruption elements, they favor the entry of a lot of light into the rooms and guarantee users a view of the surrounding landscape. In the latter case, the glazed solution becomes a transition element and continuity between inside and outside. These solutions are in fact composed of fully glazed panels, anchored to the side of the slab or to the extrados. Before choosing the type of panels, it is necessary to analyze the technical specifications and make sure that the minimum height of the parapet is equal to 1m from the walking surface. The distance between the glass plates must be minimal, so as to obstruct the passage of even small objects. From the point of view of safety, the glass that make up the parapet panels must be sufficiently resistant. Specifically, depending on the intended use of the buildings and the consequent load they will have to bear, a calculation of the minimum resistance that the parapet must comply with will be carried out.

The advantages of “all glass” parapets they are many, ranging from modern and minimal aesthetics to visual functionality, up to ease of maintenance and cleaning. In fact, if the cost of a glass parapet initially turns out to be higher than a classic metal railing, over the years it will not require renovation and consequently will allow good economic savings. Thanks to the absence of spacer and structural elements, this solution will allow a good return also from the point of view of psycho-physical well-being, in fact, the entry of light and heat will ensure thermal and visual comfort. Last but not least, the parapets in structural glass are able to respond to the most diverse aesthetic needs, thanks to the availability on the market of innovative processes and finishes that can be customized. Depending on the environment, it will be appropriate to choose the glass in the most suitable color and processing. In fact, if the sandblasting will make the crystal opaque, the printing will allow you to reproduce graphic effects and designs and again, the glass for LEDs will restore the desired atmosphere to the environment. If accessory elements are provided, such as a balustrade on the top or side of the parapet, they must be chosen in accordance with the architectural style and interior design. For example, in a modern residence a metal handrail will be perfect for a result in perfect high-tech style, while a lacquered wood profile will be indicated to give a touch of contrast.

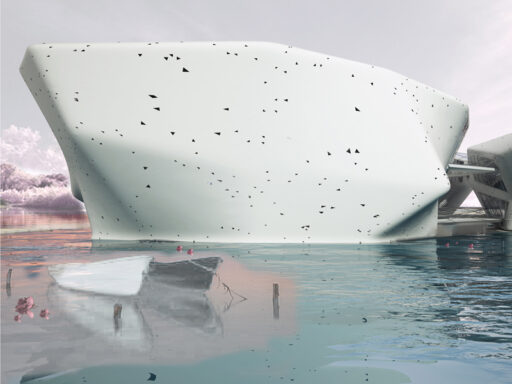

Sometimes glass parapets are part of famous architectural artefacts, an example of which is Calatrava’s Constitution Bridge in Venice. To view it click here

Types of structural glass and parapet

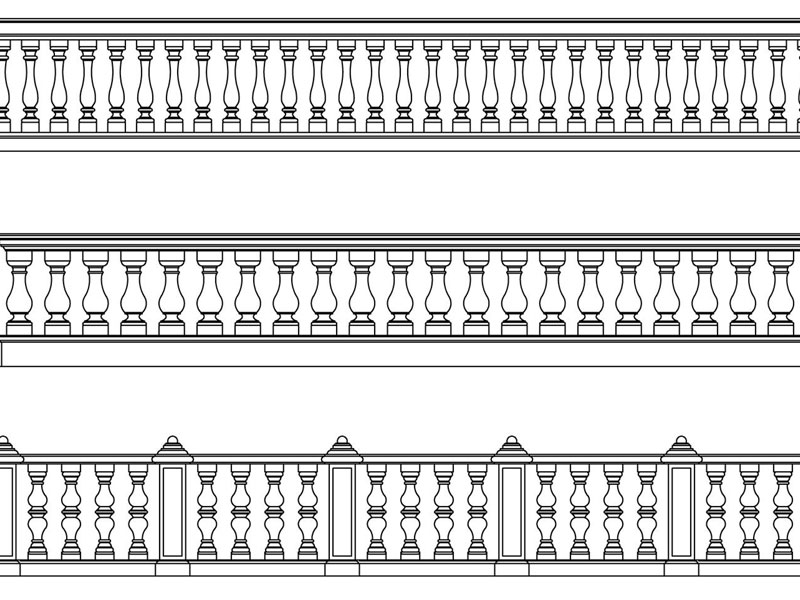

The parapets affecting terraces, balconies, stairs and other components of a building can be distinguished by physical and performance characteristics. For example, depending on the intended use of the property, the parapets must satisfy diversified needs from a structural and aesthetic point of view. In fact, residential buildings will accommodate fewer people than structures open to the public.

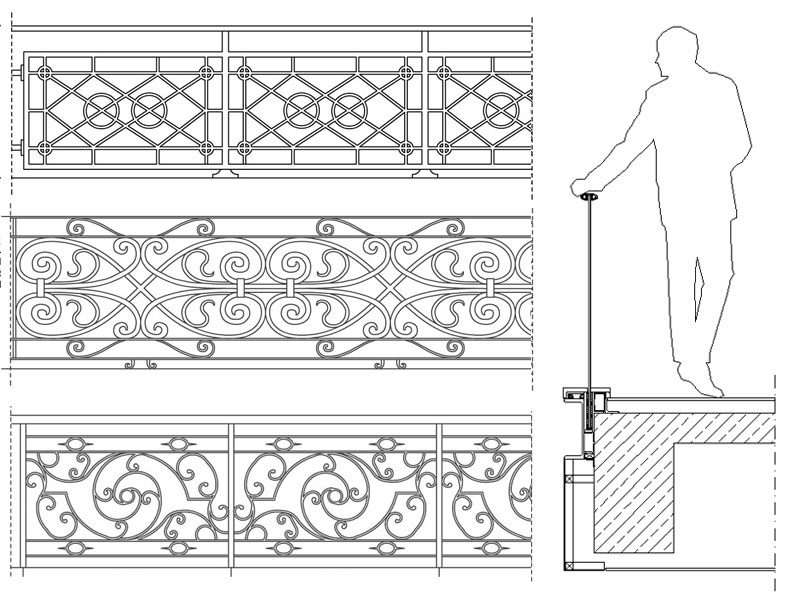

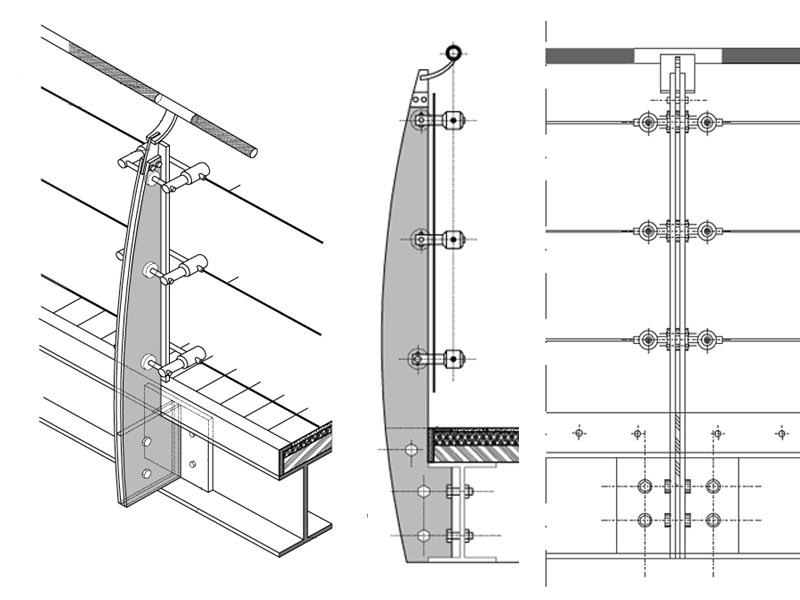

In any case, safety for users will be guaranteed everywhere. The parapet can be of different types: constrained only on one side or on both, with or without handrail, with or without subdivision of the loads on adjacent panels. Furthermore, these components can be divided into two macro categories: self-supporting or fixed on the sides; the former are divided into simple ones, when there is no supporting structure in their own right and integral, when the panels are connected by a handrail. The fixed glass parapets, on the other hand, are connected to each other and to the structure of the building through channels or special brackets. The choice between different solutions must always be linked to the need for safety, stability and shape.

As for the choice of material, it is always good to make sure that the glass is certified and complies with current legislation in terms of safety and quality. The main types of glass used in construction for the construction of parapets are:

- Monolithic tempered glass

- Laminated glass with non-tempered sheets

- Laminated glass with tempered plates

- Laminated glass with tempered plates and greater thickness

The first type of glass, despite being subjected to specific treatment to make the material more resistant, is not recommended in such solutions as it is not able to guarantee a sufficient level of safety for users. Laminated glass, on the other hand, ensures greater strength and can consist of non-tempered sheets or the mixture of a tempered and a hardened sheet. The thickness of each individual slab varies from 8 to 12 mm and the choice depends on the intended use of the building in which the parapet is inserted. The two glass panels are made to adhere through a thin sheet of plastic material which increases their safety in case of breakage. Depending on the need and function of the parapet, the laminated glass can provide for the unification of modules of two, three or four sheets. Usually two slabs are used and systems of greater thickness are provided only in specific cases such as stadiums or places that require a high flow of users.

As for the film inserted between the panels, it is a thin layer of transparent plastic that performs an important function. In fact, in the event of accidental impacts and consequent fractures, it will retain the glass fragments, guaranteeing safety and preserving the panel in place. For this purpose it is recommended to opt for a rigid plastic material, able to guarantee greater safety and strength in the remote case of breakage of all the panels. In addition, there are countless processes that provide glass for specific uses: an example are shatterproof, bulletproof and armored glass, used for banks, offices and prisons.

Thanks to the presence of diversified products on the market, it is also possible to choose colored, opaque films and sunshades that not only guarantee greater thermal comfort but also avoid unpleasant glare phenomena. Furthermore, the protective layer between the glass plates generates good sound insulation as it tends to dampen vibrations.

Photo on the right: www.casapratica.net

All types of laminated glass are based on the processing of the so-called float glass, produced starting from a compound of minerals and sand and then subjected to heat. Once solidified, the glass is cut into standardized panels or sheets made to measure to meet the most demanding and diversified needs.

The legislation relating to the installation of structural glass parapets

The Technical Standards for Construction, dated January 17, 2018, provide the provisions for the correct installation of structural glass parapets inside and outside the buildings. This legislation dictates the rules to be respected in terms of safety and resistance to loads typical of the different types of glass to be used. In fact, it is necessary to predict the behavior of the material with respect to linearly distributed static loads and dynamic loads.

The parapet is mandatory in the case of differences in height greater than 50 cm in order to prevent accidental falls and preserve individual safety. The minimum heights that the glass parapet must have and the presence of the handrail, necessary for a secure grip, are also established. Depending on the intended use of the building, the minimum height of the parapet, starting from the floor, must be equal to 1m for public and private buildings, while it can go down to 0.90m in the case of internal stairs to apartments. . In any case, each Municipality may be subject to specific variations regarding the minimum dimensions to be respected. As for the thickness of the glass panels, the choice depends on the function of the balustrade and the consequent loads that weigh on it.

The structural glass parapet has the great advantage of ensuring transparency and material continuity, without the need for interruptions generated by the insertion of load-bearing elements. However, some countries stipulate the obligation to insert a handrail or an element with a tubular profile (U-shaped) in the upper part of the glass. These elements in addition to ensuring greater safety, allow a better connection between the glass panels and the contiguous wall, making it possible to use thinner transparent sheets. If the glass structural elements do not adhere strictly to each other, the distance between them must be minimal, so as not to allow the passage of objects or human limbs that could get stuck, undermining personal safety.

The UNI 7997 Standard – Safety criteria in glass applications, establishes some essential directives for choosing the type of glass most suitable for transparent parapets. In addition to the high resistance to loads and accidental impacts, the external parapets must ensure durability with respect to the action of atmospheric agents. To this end, the panels undergo numerous resistance tests before being installed. Furthermore, it is good that the sheets are beveled, rounded on the edges and without protrusions or incongruent surface portions. Each glass must have a certificate of conformity, drawn up after checking the loads, constraints and correct dimensions according to the specific need.

As regards the necessary permits before installing a structural glass parapet, it is necessary to report the start of the activity at the offices of the municipality concerned and proceed with scaffolding and auxiliary structures, where necessary, always according to current legislation and in compliance with full safety of workers and users.

It is therefore of fundamental importance to act in full awareness from the early design stages and carefully choose components, types and materials only after conducting a structural analysis of the building that will accommodate the parapet, be it internal or external.